- 12 -

A

B

C

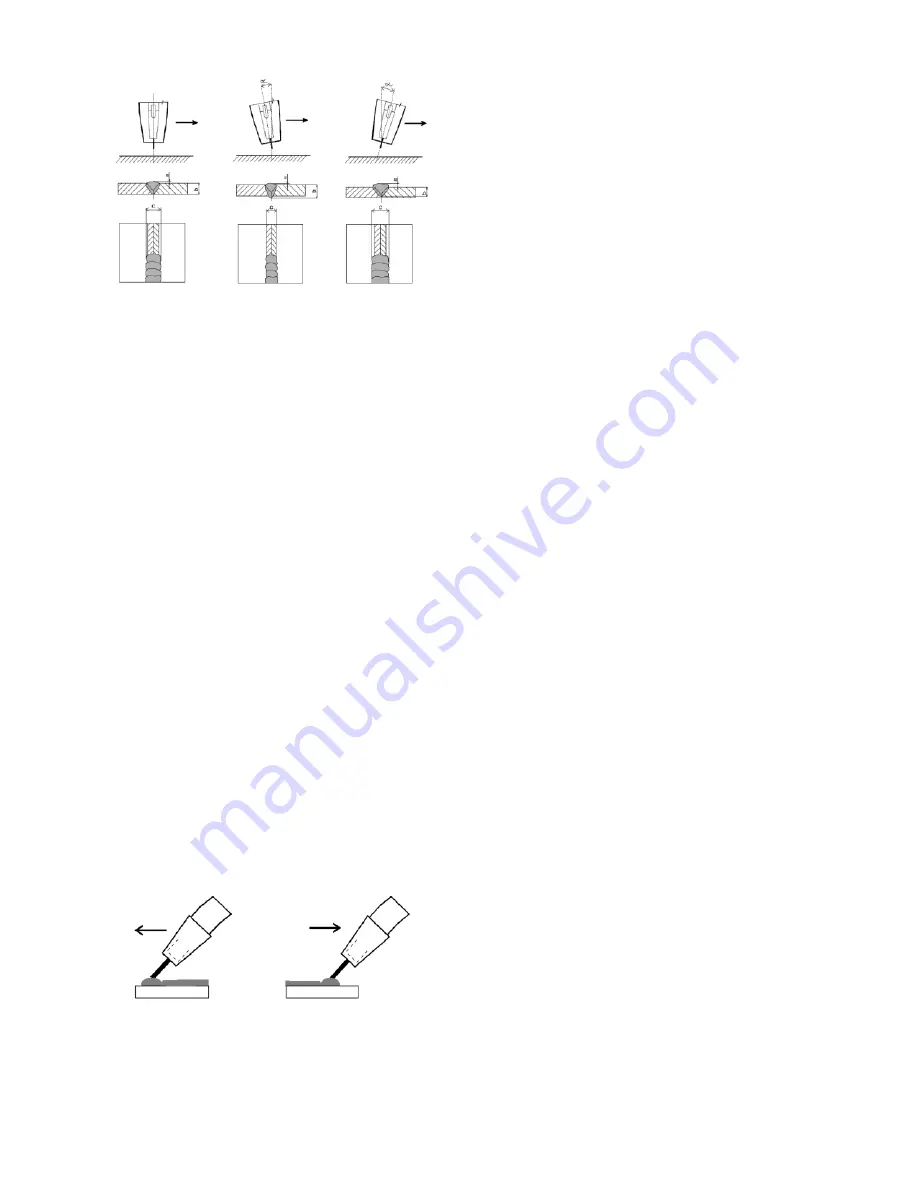

Picture 12

Gas shielded arc welding can be conducted, if the

relevant parameters are suitably selected, in all

positions

(horizontal, vertical, overhead, vertical-up

or vertical-down and across, at the same time in

these positions). In horizontal or vertical positions,

the usual gripping of the torch is in the angle of 30°.

In the case of more thick layers, the welding process

is performed by light drawing. The most suitable grip

on the torch for the optimum coverage of the weld

place by shielding gas is vertical (neutral) positioning

of the torch (Pic. 11 A). However, in this position it is

difficult to watch the welded place (it is hidden be-

hind the gas nozzle). For this reason, the torch

should be slightly tilted (Pic. 11 BC). On the other

hand, if the torch tilt is excessively off this position,

there is a danger of sucking air into the shield gas,

which might negatively influence the weld quality.

WELDING BY PRESSING AND DRAWING

Slight moves with “pressing” are used in vertical-up

welding and horizontal overhead welding (Pic. 13).

Only in vertical-down welding the torch is gripped in

the neutral or slightly “drawing” position. The verti-

cal-down welding is used mostly for thin metal

sheets, because there is a risk of a poor connection

with thick sheets; the molten metal tends to pour

down along the connection and “overtake” the weld,

particularly when the molten metal is too liquid

because of high voltage. Such method requires a

high degree of expertise and experience (Pic. 14).

Picture 13

Picture 14

Maintenance

WARNING:

Before carrying out any inspection of the

inside of the generator, disconnect the system from

the supply.

In planning of maintenance procedures, the level

and circumstances of the apparatus usage must be

taken into account. Careful handling and preventive

maintenance helps to avoid unnecessary failures and

defects.

If required by the apparatus working conditions,

the inspection and maintenance intervals must be

shortened. If the apparatus is used in a very dusty

environment (conduction dust), then intervals will

be as short as twice a month.

REGULAR MAINTENANCE AND INSPECTIONS

Conduct the inspections according to the relevant

Czech Standard (EN 60974-4.). Before any use of the

apparatus, check the conditions of the welding and

power supply cables. Do not use damaged cables!

Visual inspections include:

1.

Torch, welding current return clamp

2.

Power supply network

3.

Welding circuit

4.

Covers

5.

Controlling and indicating elements

6.

Apparatus condition in general

EVERY HALF A YEAR

Remove the plug from the socket outlet and wait for

two minutes (to allow for discharging of capacitors

inside the apparatus). Then remove the cover of the

apparatus. Clean all internal power supply connec-

tions from dust and dirt. Where they are loose,

tighten them.

Clean all internal parts of the apparatus from dust

and dirt using a soft brush of vacuum cleaner.

NOTE:

Be careful when using compressed air in order

to not damage any parts.

Never use any solvents or diluents (such as acetone,

etc.); plastic material and front panel lettering could

be damaged in such procedures.

Only sufficiently qualified technicians (electrical

engineers) may repair the apparatus.

SPARE PARTS

Original spare parts have been specially designed for

our equipment. The use of non-original spare parts

may cause variations in performance or reduce the

foreseen level of safety. We decline all responsibility

for the use of non-original spare parts.

THE GENERATOR

As these systems are completely static, proceed as

follows:

Summary of Contents for MW2040

Page 19: ...19 2080...