Repair

7-23

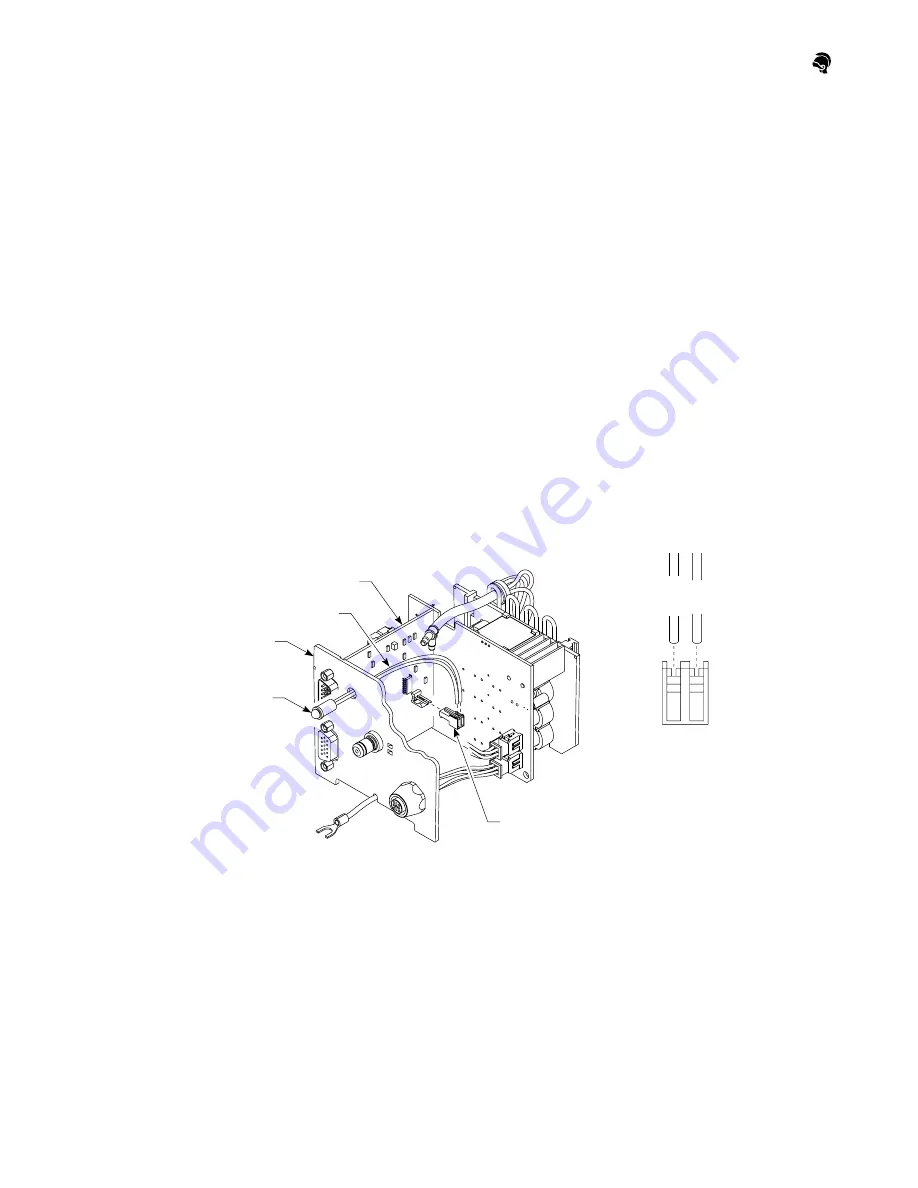

7) Disconnect the LED connector from the CPU board. (See Figure 7V.)

8) Remove the connector from the LED wires.

9) Remove the LED and wires through the back plate.

10) Install the new LED and the wires through the back plate.

11) Install the connector onto the LED wires.

12) Place the new LED connector in the appropriate location on the CPU

13) Replace the printhead assembly into the printhead enclosure.

14) Replace the printhead cover.

15) Tighten the four screws on the printhead cover.

16) Secure the printhead ground wire to the printhead bracket with the

screw.

17) Reconnect the ink line, data lines, and power cables to the back of the

printhead.

18) Turn on the printhead power supply.

Figure 7V: Replacing the LED

Back Plate

LED Wires

CPU Board

Black

Red

LED

LED Connector

Top View of

LED Connector

Pin Assignments

1 2

Note: Some components have been

removed for illustration purposes.

Summary of Contents for PatrionPlus

Page 41: ...Installation ii 29669 02080 Rev AF...

Page 72: ...Operation iv 29669 02080 Rev AG...

Page 153: ...Maintenance ii 29669 02012 Rev AF...

Page 161: ...Troubleshooting ii 29669 02080 Rev AF...

Page 184: ...Repair ii 29669 02080 Rev AF...

Page 212: ...Parts List ii 29669 02080 Rev AF...