3 - 15

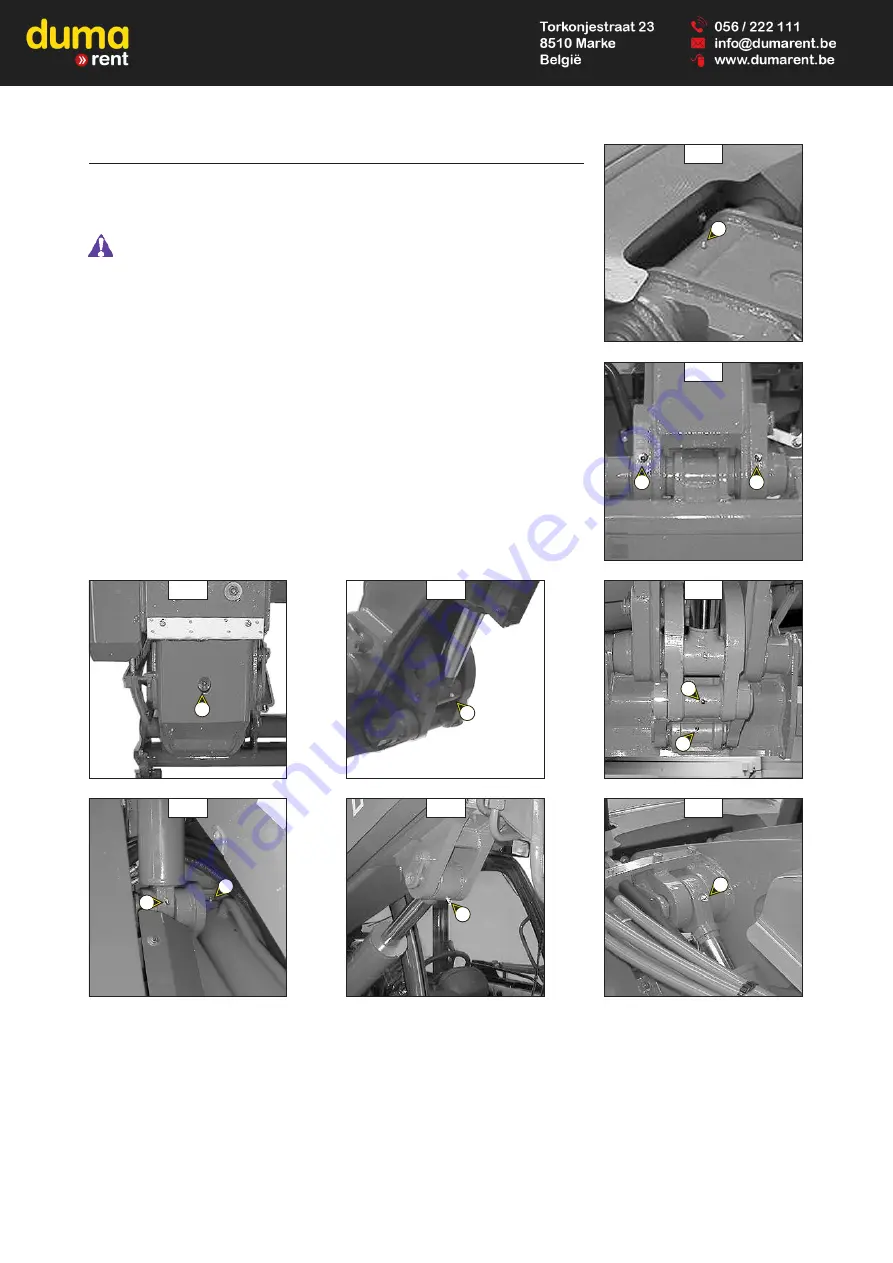

B4 - JIB

GREASE

To be carried out weekly, if the lift truck has been operated for less than 50 hours during

the week.

In the event of prolonged use in an extremely dusty or oxidising atmosphere, reduce this

interval to 10 working hours or every day.

Clean and lubricate the following points with grease (see: 3 - MAINTENANCE: LUBRICANTS

AND FUEL) and remove the surplus of grease.

1 - Lubricators of the jib axle (1 lubricator) (fig. B4/1).

2 - Lubricators of the carriage axle (2 lubricators) (fig. B4/2).

3 - Lubricator of the tilt cylinder foot axle (1 lubricator) (fig. B4/3).

4 - Lubricator of the tilt cylinder head axle (1 lubricator) (fig. B4/4).

5 - Lubricators of the carriage connecting rod axle (2 lubricators) (fig. B4/5).

6 - Lubricator of the lifting cylinder foot axle (1 lubricator) (fig. B4/6).

7 - Lubricator of the lifting cylinder head axle (1 lubricator) (fig. B4/7).

8 - Lubricator of the compensation cylinder foot axle (1 lubricator) (fig. B4/6).

9 - Lubricator of the compensation cylinder head axle (1 lubricator) (fig. B4/8).

B4/1

B4/2

2

2

1

4/3

4/4

4/6

4/7

4/8

4/5

3

4

5

5

8

6

7

9

Summary of Contents for B-E2 Series

Page 2: ......

Page 4: ......

Page 5: ...1 1 1 OPERATING AND SAFETY INSTRUCTIONS...

Page 6: ...1 2...

Page 30: ...1 26...

Page 31: ...2 1 2 DESCRIPTION 2 DESCRIPTION...

Page 32: ...2 2...

Page 47: ...2 17...

Page 65: ...2 35...

Page 75: ...3 1 3 MAINTENANCE 3 MAINTENANCE...

Page 76: ...3 2...

Page 78: ...3 4...

Page 97: ...3 23...

Page 103: ...3 29...

Page 107: ...3 33...

Page 109: ...3 35...

Page 116: ...4 2...

Page 118: ...4 4...

Page 127: ...4 13...