3 - 32

E6 - SEAT BELT

CHECK

SEAT BELT WITH TWO ANCHORING POINTS

- Check the following points:

• Fixing of the anchoring points on the seat.

• Cleanness of the strap and the locking mechanism.

• Triggering of the locking mechanism.

• Condition of the strap (cuts, curled edges).

REELED SEAT BELT WITH TWO ANCHORING POINTS

- Check the points listed above together with the following points:

• The correct winding of the belt.

• Condition of the reel guards.

• Roller locking mechanism when the strap is given a sharp tug.

NOTE: After an accident, replace the seat belt.

Under no circumstances should you use the lift truck if the seat belt is faulty (fixing, locking, it has cuts or tears, etc). Repair or replace

the seat belt immediately.

E7 - FRONT AND REAR WHEELS REDUCERS OIL

DRAIN

Place the lift truck on level ground with the I.C. engine stopped and the reducers oil still

warm.

Dispose the drain oil in an ecological manner.

- Drain and change each front wheel reducer.

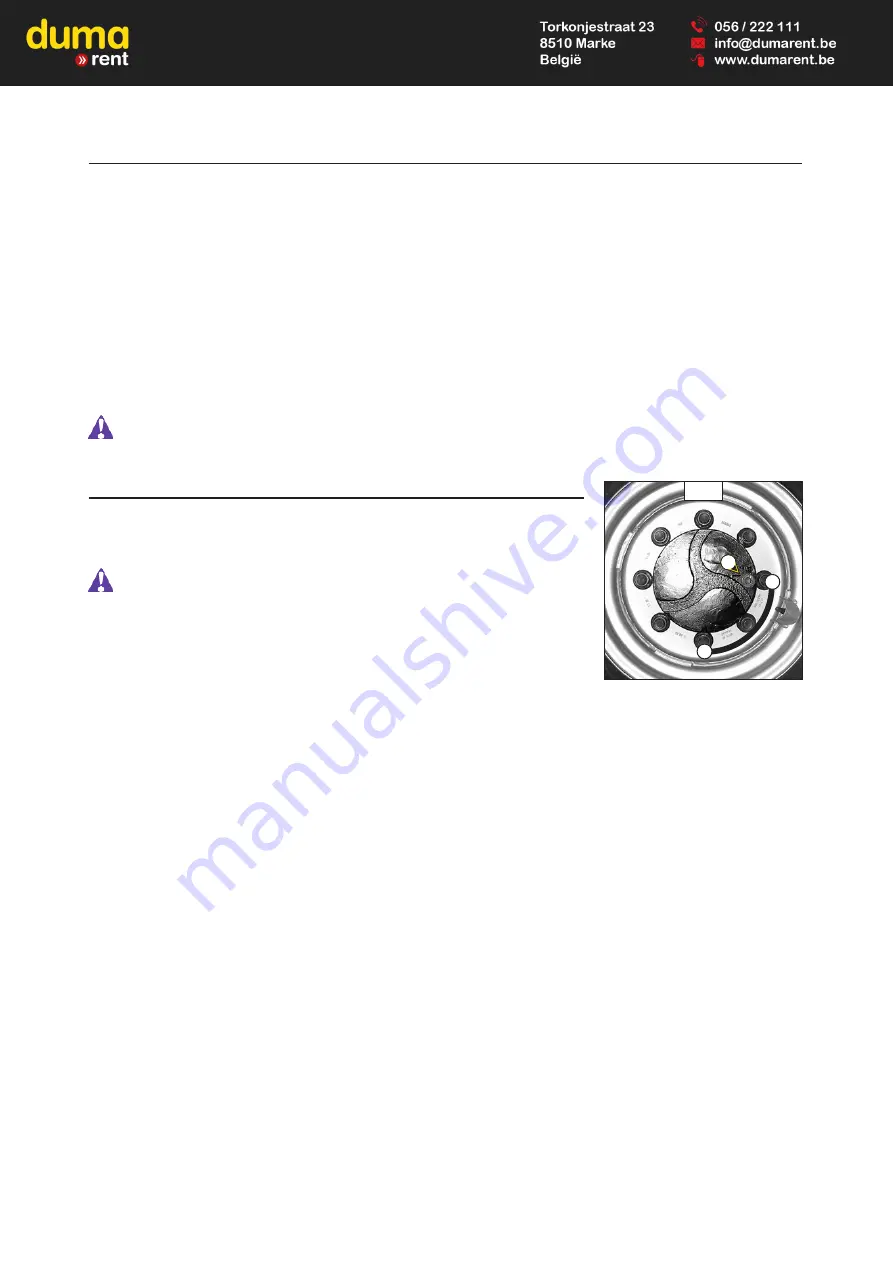

- Place drain plug 1 (fig. E7) in position A.

- Place a container under the drain plug and unscrew the plug.

- Let the oil drain fully.

- Place the drain por t in position B, i.e. in a level por t.

- Fill up with oil (see: 3 - MAINTENANCE: LUBRICANTS AND FUEL) by level por t 1 (fig. E7).

- The level is correct when the oil level is flush with the edge of the hole.

- Refit and tighten the drain plug 1 (fig. E7) (tightening torque 34 to 49 N.m).

- Repeat this operation on each rear wheel reducer.

E7

B

A

1

Summary of Contents for B-E2 Series

Page 2: ......

Page 4: ......

Page 5: ...1 1 1 OPERATING AND SAFETY INSTRUCTIONS...

Page 6: ...1 2...

Page 30: ...1 26...

Page 31: ...2 1 2 DESCRIPTION 2 DESCRIPTION...

Page 32: ...2 2...

Page 47: ...2 17...

Page 65: ...2 35...

Page 75: ...3 1 3 MAINTENANCE 3 MAINTENANCE...

Page 76: ...3 2...

Page 78: ...3 4...

Page 97: ...3 23...

Page 103: ...3 29...

Page 107: ...3 33...

Page 109: ...3 35...

Page 116: ...4 2...

Page 118: ...4 4...

Page 127: ...4 13...