08028-0D\H5250\94.08.12

B 11 00 0

Fuel Oil Cleaning Recommendations

General

Centrifuging

Fuel oils should always be considered as contami-

nated upon delivery and should therefore be

thoroughly cleaned to remove solids as well as liquid

contaminants before use.

The solid contaminants in the fuel oil are mainly rust,

sand, dust and refinery catalysts. Liquid contami-

nants are mainly water, i.e. either fresh water or salt

water.

Impurities in the fuel can cause damage to fuel

pumps and fuel valves, and can lead to increased

cylinder liner wear and deterioration of the exhaust

valve seats. Also increased fouling of gas ways and

turbocharger blades may result from the use of

inadequately cleaned fuel oil. Effective cleaning can

only be ensured by using a centrifuge.

We recommend that the capacity of the installed

centrifuge should, at least, be according to the

centrifuge maker's instructions.

Cleaning of distillate fuel such as ISO 8217 classes

DMX to DMB is generally not necessary. But han-

dling of a liquid fuel on board ships gives a risk of

contamination with sea water. Therefore it is a good

idea to centrifuge all fuel on board ships.

Fuel classes DMC to RMH55 require a treatment

with centrifuge in all cases.

Automatic centrifuges must be used. Fuel types

RMK35 to RMK55 require centrifuges capable to

handle up to 1010 kg/m

3

density.

To obtain optimum cleaning it is of the utmost impor-

tance that the centrifuge is operated with a fuel oil

viscosity as low as possible, i.e. that the highest

possible temperature is maintained in the centrifuge

oil preheater.

Supplementary Equipment

Experience proves that if the centrifugal installation

is dimensioned and installed correctly – and oper-

ated correctly according to the supplier's instructions

– this is a sufficient way of cleaning the fuel.

All supplementary equipment, such as the 10 m

m

nominal filter, will have a positive effect and may

contribute to longer intervals between overhauls.

Also, supplementary equipment will reduce the op-

eration costs.

This equipment can give difficulties if incorrectly

installed, However if correctly installed and operated

can with some fuels give benefits in lower wear and

sludge formation.

1655267-1.3

Page 1 (1)

99.33

Summary of Contents for L28/32H

Page 4: ......

Page 5: ...Introduction I 00...

Page 6: ......

Page 8: ......

Page 10: ......

Page 11: ...Designation of Cylinders In Line 98 19 1607568 0 1 Page 1 1 I 00 15 0...

Page 12: ......

Page 18: ......

Page 19: ...General information D 10...

Page 20: ......

Page 22: ......

Page 24: ......

Page 26: ......

Page 30: ......

Page 32: ......

Page 34: ......

Page 36: ......

Page 37: ...Basic Diesel Engine B 10...

Page 38: ......

Page 44: ......

Page 45: ...99 40 B 10 01 1 L28 32H Cross Section 1607528 5 2 Page 1 1...

Page 46: ......

Page 48: ......

Page 50: ......

Page 52: ......

Page 54: ......

Page 58: ......

Page 59: ...1607566 7 1 Page 1 1 Engine Rotation Clockwise B 10 11 1 General 98 18...

Page 60: ......

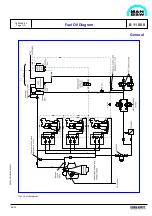

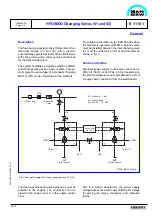

Page 61: ...Fuel Oil System B 11...

Page 62: ......

Page 68: ......

Page 72: ......

Page 74: ......

Page 76: ......

Page 79: ...Lubrication Oil System B 12...

Page 80: ......

Page 86: ......

Page 88: ......

Page 91: ...Cooling Water System B 13...

Page 92: ......

Page 98: ......

Page 106: ......

Page 108: ......

Page 112: ......

Page 113: ...Compressed Air System B 14...

Page 114: ......

Page 118: ......

Page 119: ...Combustion Air System B 15...

Page 120: ......

Page 124: ......

Page 126: ...Fig 1 Jet system 1639456 5 0 Page 2 2 Lambda Controller 93 44 L28 32H B 15 11 1...

Page 127: ...Exhaust Gas System B 16...

Page 128: ......

Page 136: ......

Page 140: ......

Page 142: ......

Page 144: ......

Page 146: ......

Page 147: ...Speed Control System B 17...

Page 148: ......

Page 150: ......

Page 152: ......

Page 153: ...Monitoring Equipment B 18...

Page 154: ......

Page 156: ......

Page 158: ......

Page 159: ...Safety and Control System B 19...

Page 160: ......

Page 164: ......

Page 166: ......

Page 177: ...Foundation B 20...

Page 178: ......

Page 180: ......

Page 183: ...Test running B 21...

Page 184: ......

Page 186: ......

Page 187: ...Spare Parts E 23...

Page 188: ......

Page 190: ......

Page 191: ...99 35 1607521 2 6 Page 1 1 Recommended Wearing Parts E 23 04 0 L28 32H...

Page 192: ......

Page 195: ...Tools P 24...

Page 196: ......

Page 200: ......

Page 202: ......

Page 203: ...Preservation and Packing B 25...

Page 204: ......

Page 206: ......

Page 208: ......

Page 210: ......

Page 211: ...Alternator G 50...

Page 212: ......

Page 216: ......

Page 218: ......