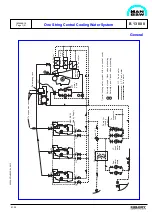

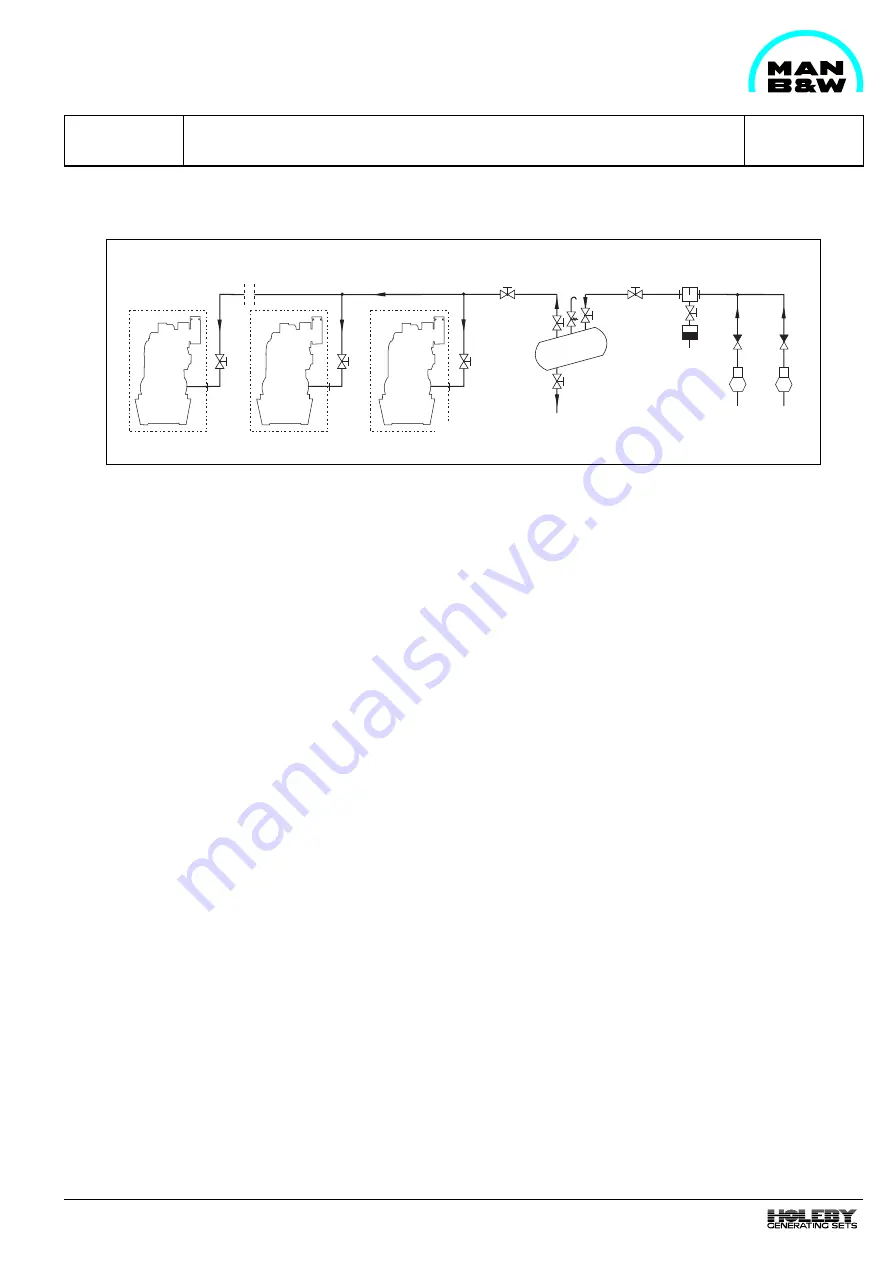

Engine

No. N

Engine

No. 2

Engine

No. 1

Starting air

bottle

Oil and water

separator

Drain to bilge

Air compressors

K1

K1

K1

MAN B&W,

Holeby supply

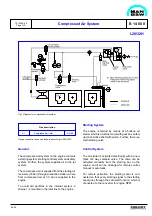

Fig. 1. Diagram for Compressed Air System.

Design of External System

The external compressed air system should be

common for both propulsion engines and GenSet

engine.

Separate tanks shall only be installed in case of

turbine vessels, or if the GenSets in engined vessels

are installed far away from the propulsion plant.

The design of the air system for the actual plant must

be according to the rules of the relevant classification

society.

For the engines' internal compressed air system,

please see B 14 00 0 "Internal Compressed Air

System".

An oil and water separator should be mounted in the

line between the compressor and the air receivers,

and the separator should be equipped with auto-

matic drain facilities.

Each engine needs only one connection for com-

pressed air, see the internal diagram.

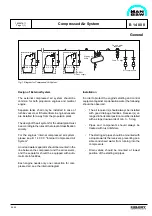

Installation

In order to protect the engine's starting and control

equipment against condensation water the following

should be observed:

-

The air receiver(s) should always be installed

with good drainage facilities. Receiver(s) ar-

ranged in horizontal position must be installed

with a slope downwards of min. 3 - 5 deg.

-

Pipes and components should always be

treated with rust inhibitors.

-

The starting air pipes should be mounted with

a slope towards the receivers, preventing pos-

sible condensed water from running into the

compressors.

-

Drain valves should be mounted at lowest

position of the starting air pipes.

95.09

Compressed Air System

General

B 14 00 0

1624476-1.1

Page 1 (1)

Summary of Contents for L28/32H

Page 4: ......

Page 5: ...Introduction I 00...

Page 6: ......

Page 8: ......

Page 10: ......

Page 11: ...Designation of Cylinders In Line 98 19 1607568 0 1 Page 1 1 I 00 15 0...

Page 12: ......

Page 18: ......

Page 19: ...General information D 10...

Page 20: ......

Page 22: ......

Page 24: ......

Page 26: ......

Page 30: ......

Page 32: ......

Page 34: ......

Page 36: ......

Page 37: ...Basic Diesel Engine B 10...

Page 38: ......

Page 44: ......

Page 45: ...99 40 B 10 01 1 L28 32H Cross Section 1607528 5 2 Page 1 1...

Page 46: ......

Page 48: ......

Page 50: ......

Page 52: ......

Page 54: ......

Page 58: ......

Page 59: ...1607566 7 1 Page 1 1 Engine Rotation Clockwise B 10 11 1 General 98 18...

Page 60: ......

Page 61: ...Fuel Oil System B 11...

Page 62: ......

Page 68: ......

Page 72: ......

Page 74: ......

Page 76: ......

Page 79: ...Lubrication Oil System B 12...

Page 80: ......

Page 86: ......

Page 88: ......

Page 91: ...Cooling Water System B 13...

Page 92: ......

Page 98: ......

Page 106: ......

Page 108: ......

Page 112: ......

Page 113: ...Compressed Air System B 14...

Page 114: ......

Page 118: ......

Page 119: ...Combustion Air System B 15...

Page 120: ......

Page 124: ......

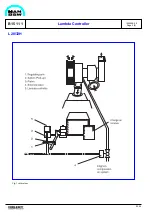

Page 126: ...Fig 1 Jet system 1639456 5 0 Page 2 2 Lambda Controller 93 44 L28 32H B 15 11 1...

Page 127: ...Exhaust Gas System B 16...

Page 128: ......

Page 136: ......

Page 140: ......

Page 142: ......

Page 144: ......

Page 146: ......

Page 147: ...Speed Control System B 17...

Page 148: ......

Page 150: ......

Page 152: ......

Page 153: ...Monitoring Equipment B 18...

Page 154: ......

Page 156: ......

Page 158: ......

Page 159: ...Safety and Control System B 19...

Page 160: ......

Page 164: ......

Page 166: ......

Page 177: ...Foundation B 20...

Page 178: ......

Page 180: ......

Page 183: ...Test running B 21...

Page 184: ......

Page 186: ......

Page 187: ...Spare Parts E 23...

Page 188: ......

Page 190: ......

Page 191: ...99 35 1607521 2 6 Page 1 1 Recommended Wearing Parts E 23 04 0 L28 32H...

Page 192: ......

Page 195: ...Tools P 24...

Page 196: ......

Page 200: ......

Page 202: ......

Page 203: ...Preservation and Packing B 25...

Page 204: ......

Page 206: ......

Page 208: ......

Page 210: ......

Page 211: ...Alternator G 50...

Page 212: ......

Page 216: ......

Page 218: ......