13 ENGLISH

Choose and use nails so that the penetration depth into

concrete ranges 10 mm (3/8") - 15 mm (5/8"). Refer to

the table below.

Wood thick-

ness (A)

Nail length (B)

Penetration depth

into concrete (C)

30 mm - 35 mm

(1-3/16" - 1-3/8")

45 mm (1-3/4")

10 mm - 15 mm

(3/8" - 5/8")

35 mm - 40 mm

(1-3/8" - 1-5/8")

50 mm (2")

50 mm - 55 mm

(2" - 2-3/16")

65 mm (2-1/2")

►

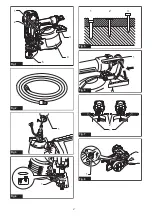

Fig.24

NOTICE:

Use the tool only for soft concrete built

up not so long before.

Driving nails into hard concrete

may cause nail bending or nailing into insufficient depth.

NOTICE:

When penetrating into concrete deeper

than 15 mm (5/8"), nails may not be driven sufficiently.

Cutting linked sheet

CAUTION:

Always disconnect the air hose

from the tool before removing the linked sheet.

When using linked sheet nails, the linked sheet will be

ejected from the driver guide as you drive the nails. Tear

away the ejected sheet by twisting as shown in the figure.

►

Fig.25:

1.

Ejected linked sheet

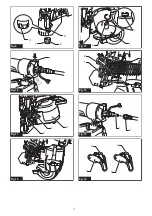

Removing jammed nails

CAUTION:

Always lock the trigger by turning

the trigger lock lever to the lock position , and

disconnect the hose before removing jammed

nails. Also remove the nails from the magazine

before cleaning a jam.

1.

Depress the latch lever and open the door. Open

the magazine cap and remove the nail coil.

2.

Insert a small metal rod into the nail ejection port

and hit it with a hammer lightly.

►

Fig.26:

1.

Metal rod

2.

Nail ejection port

3.

Hammer

3.

Remove the jammed nail with a flat-blade screw

-

driver or other similar tool.

►

Fig.27

4.

Reset the nail coil and close the magazine cap

and the door.

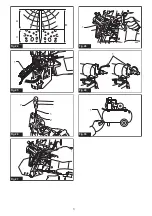

MAINTENANCE

CAUTION:

Before attempting to perform

inspection or maintenance, always lock the trigger

by turning the trigger lock lever to the lock posi-

tion , and disconnect the air hose from the tool.

NOTICE:

Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

Cleaning of tool

Iron dust that adhere to the magnet can be blown off by

using an air duster.

►

Fig.28:

1.

Magnet

Storage

When not in use, disconnect the hose. Then cap the air

fitting with the cap. Store the nailer in a warm and dry

place.

►

Fig.29:

1.

Cap

Maintenance of compressor, air set

and air hose

After operation, always drain the compressor tank and

the air filter. If moisture is allowed to enter the tool,

it may result in poor performance and possible tool

failure.

►

Fig.30:

1.

Drain cock

Keep the air hose away from heat (over 60°C, over

140°F), away from chemicals (thinner, strong acids or

alkalis). Also, route the hose away from obstacles which

it may become dangerously caught on during operation.

Hoses must also be directed away from sharp edges

and areas which may lead to damage or abrasion to

the hose.

To maintain product SAFETY and RELIABILITY,

repairs, any other maintenance or adjustment should

be performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

OPTIONAL

ACCESSORIES

CAUTION:

These accessories or attachments

are recommended for use with your Makita tool

specified in this manual.

The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or attachment

for its stated purpose.

If you need any assistance for more details regard-

ing these accessories, ask your local Makita Service

Center.

• Nails

•

Air hose

•

Safety goggles

NOTE:

Some items in the list may be included in the

tool package as standard accessories. They may

differ from country to country.