12 ENGLISH

OPERATION

CAUTION:

Make sure all safety systems are in

working order before operation.

CAUTION:

When operating the tool, do not

close the face to the tool. Also keep hands and

feet away from the ejection port area.

CAUTION:

When not operating the tool,

always lock the trigger by turning the trigger lock

lever to the lock position .

CAUTION:

Make sure that the trigger is locked

when the trigger lock lever is set to the lock position .

Checking proper action before operation

Before operation, always check following points.

— Make sure that the tool does not operate only by

connecting the air hose.

— Make sure that the tool does not operate only by

pulling the trigger.

— Make sure that the tool does not operate only by

placing the contact element against the workpiece

without pulling the trigger.

— In single sequential actuation mode, make sure

that the tool does not operate when pulling the

trigger first and then placing the contact element

against the workpiece.

Nailing method

To prevent the trigger from being accidentally pulled,

the trigger lock lever is provided.

To lock the trigger, turn the trigger lock lever to the lock position .

To use the tool, turn the trigger lock lever to the unlock

position .

►

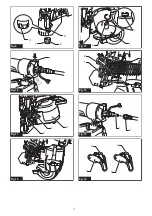

Fig.20:

1.

Trigger lock lever

2.

Trigger

Single sequential actuation

CAUTION:

Do not place the contact element

against the workpiece with excessive force. Also, pull the

trigger fully and hold it on for 1-2 seconds after nailing.

Even in the “Single sequential actuation” mode, half-

pulled trigger causes an unexpected nailing, when the

contact element re-contacts the workpiece.

Place the contact element against the workpiece and

pull the trigger fully.

After nailing, release the contact element, and then

release the trigger.

►

Fig.21

Contact actuation

Pull the trigger first and then place the contact element

against the workpiece.

►

Fig.22

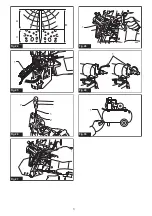

Nailing on steel plate

WARNING:

When nailing on the C-shaped

steel, limit the thickness to 3.2 mm (1/8") or thin-

ner.

Otherwise the tool will bounce severely and a

nail struck back, causing serious injuries.

WARNING:

Use hardened nails only for steel

plate.

Using other purposed nails may cause serious

injuries.

WARNING:

When nailing, hold the tool so that

it stands upright to the driving surface.

Slanted

nailing may cause nails to strike back, causing seri-

ous injuries.

WARNING:

Do not use the tool for fastening

a corrugated plate or the C-shaped steel directly.

It may cause nails to strike back, causing serious

injuries.

WARNING:

Do not use the tool for nailing on

ceiling or roof.

Choose and use nails 10 mm (3/8") or much longer than

total thickness of all workpiece to be fastened. Refer to

the table below.

Material thick-

ness including

C-shaped steel (A)

C-shaped steel (B)

thickness

Nail length (C)

30 mm - 35 mm

(1-3/16" - 1-3/8")

1.6 mm - 3.2 mm

(1/16" - 1/8")

45 mm (1-3/4")

35 mm - 40 mm

(1-3/8" - 1-5/8")

50 mm (2")

►

Fig.23

NOTICE:

Depending on the hardness and

total thickness of all workpiece in combination,

enough fastening may not be obtained. Nailing on

steel plate with excessive depth may extremely

reduce the fastening force.

Before nailing, adjust

the nailing depth properly.

NOTICE:

Nailing on the steel plate makes the

driver prematurely worn out and it may cause nail

jamming.

When the driver is worn, replace it with a

new one.

Nailing on concrete

WARNING:

Use hardened nails only for con-

crete.

Using other purposed nails may cause serious

injuries.

WARNING:

Do not nail directly on the con-

crete or do not fasten directly the steel plate to

the concrete.

It may cause concrete fragments to fly

off or nails to strike back, causing serious injuries.

WARNING:

When nailing, hold the tool so that

it stands upright to the driving surface.

Slanted

nailing may cause concrete fragments to fly off or

nails to strike back, causing serious injuries.

WARNING:

Do not use the tool for fastening

an object to hang something such as sewer pipe.