11 ENGLISH

Nose adapter

To prevent the surface of workpiece from being

scratched or damaged, use the nose adapter.

To detach the nose adapter from its housing base, pull

the nose adapter in the direction of the arrow.

►

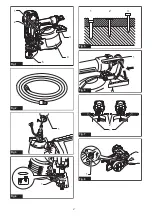

Fig.8:

1.

Nose adapter

To attach the nose adapter to the contact element, press it onto

the contact element until the recessed parts in four places inside

the nose adapter fit in four protrusions of the contact element.

►

Fig.9:

1.

Nose adapter

2.

Contact element

3.

Protrusion

4.

Recessed part

Air duster

CAUTION:

Do not aim the ejection port of the air

duster to someone. Also, keep your hands and foot

away from the ejection port.

If the air duster button is

accidentally pushed, it may cause a personal injury.

CAUTION:

Always check your surroundings

before using the air duster.

Blown dust or objects

may hit someone.

CAUTION:

Do not connect or disconnect the

air hose while pushing the air duster button.

The air supplied to the tool can also be used as an air

duster. You can clean the work area by pressing the

button on the grip end.

►

Fig.10:

1.

Button

NOTICE:

After using the air duster, the driving force

of the tool will temporarily decline. Wait until the air

pressure recovers in this case.

NOTICE:

Perform a test blow if you use the air

duster immediately after the oil was applied. The oil

may be sprayed with the air.

ASSEMBLY

CAUTION:

Before carrying out any work on

the tool, always lock the trigger by turning the

trigger lock lever to the lock position , and

disconnect the air hose from the tool.

Loading nailer

CAUTION:

Do not use deformed nails or

linked sheet.

1.

Disconnect the air hose.

2.

Depress the latch lever and open the door and magazine cap.

►

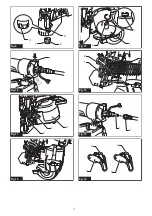

Fig.11:

1.

Latch lever

2.

Door

3.

Magazine cap

►

Fig.12

3.

Turn the adjust shaft and set the step of the

change plate suitable for the nail length. Make sure that

the arrow points to the corresponding graduation incre-

ment of the nail length marked on the adjust shaft.

►

Fig.13:

1.

Change plate

2.

Adjust shaft

3.

Arrow

NOTICE:

If the tool is operated with the change

plate set to the wrong step, it may result in poor nail

feeding or tool malfunction.

4.

Place the nail coil over the change plate and

uncoil enough nails to reach the nail rail.

Then place the first nail in the nail rail and the second

nail in the feed claw. Also, place other uncoiled nails on

feeder body.

►

Fig.14:

1.

Nail rail

2.

Feed claw

5.

Check that the nail coil is set properly in the magazine.

6.

Close the magazine cap carefully. Then with depress-

ing the latch lever, close the door until the latch lever locks.

Connecting air hose

CAUTION:

Do not connect the air hose with

a finger on the trigger.

An unexpected driving will

cause serious injury.

►

Fig.15:

1.

Air fitting

2.

Air socket

Slip the air socket of the air hose onto the air fitting on

the tool. Be sure that the air socket locks firmly into

position when installed onto the air fitting.

A hose coupling must be installed on or near the tool in

such a way that the pressure reservoir will discharge at

the time the air supply coupling is disconnected.

Changing the trigger for contact

actuation mode

CAUTION:

Always disconnect the air hose and

unload the tool with nails before replacing the trigger.

CAUTION:

After the trigger replacement, always

check that the tool operates properly before actual

work. Do not load the tool with any nails before

checking the function to avoid unexpected nailing.

The trigger for single sequential actuation mode is facto-

ry-installed. To change the nailing mode to contact actuation,

replace the trigger part with the one for contact actuation.

►

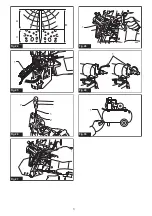

Fig.16:

1.

Trigger for contact actuation

2.

Silver part

3.

Trigger for single sequential actuation

4.

Black part

1.

Turn the trigger lock lever to the lock position .

►

Fig.17:

1.

Trigger lock lever

2.

Push the pin securing the trigger from the ure-

thane washer side, and then remove the urethane

washer. Then pull out the pin and remove the trigger.

►

Fig.18:

1.

Pin

2.

Urethane washer

3.

Trigger

3.

Set the trigger assembly for contact actuation.

With pushing in the hinged part inward, set the trigger so that

the hinged part is under the rod of the valve in the housing.

►

Fig.19:

1.

Hinged part

2.

Rod of the valve

4.

Insert the pin to the hole and secure it by urethane washer.

5.

Connect the air hose, and make sure that the

tool operates properly. Refer to the section “Checking

proper action before operation”.

NOTE:

To set back to single sequential actuation,

follow the procedures for changing the trigger above.