Reviews:

No comments

Related manuals for PKT-2-J50 SD

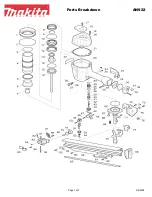

AN922

Brand: Makita Pages: 3

AG125

Brand: Makita Pages: 3

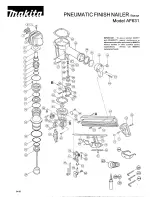

AF631

Brand: Makita Pages: 2

AF503

Brand: Makita Pages: 32

SuperSider CN565S2(CE)

Brand: Max Pages: 14

CHN50399

Brand: Campbell Hausfeld Pages: 18

CHN20103

Brand: Campbell Hausfeld Pages: 24

CHN10202

Brand: Campbell Hausfeld Pages: 24

CHN70900

Brand: Campbell Hausfeld Pages: 60

Brad Nailer CHN70200

Brand: Campbell Hausfeld Pages: 60

KJ 45/S

Brand: FAR Pages: 80

500326

Brand: RHINO Pages: 12

EG111

Brand: Rapid Pages: 28

DENT MASTER CT3789

Brand: Neilsen Pages: 8

DPT353Y1J

Brand: Makita Pages: 24

351.184300

Brand: Craftsman Pages: 16

351.184310

Brand: Craftsman Pages: 12

T250S-F16P

Brand: Paslode Pages: 20