Reviews:

No comments

Related manuals for 351.184300

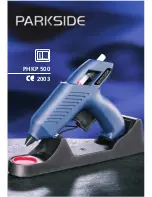

PHP 500 A1 - 3

Brand: Parkside Pages: 36

PHKP 500 SE - MANUEL 4

Brand: Parkside Pages: 8

PNKP 105 A1

Brand: Parkside Pages: 36

Druck PV 622

Brand: GE Pages: 55

Matt Gun II

Brand: Freeman Pages: 28

SGY-NR-KITV

Brand: Blue Hawk Pages: 39

FN1665.2

Brand: Paslode Pages: 12

CNW45R

Brand: Paslode Pages: 13

FN1550A26

Brand: Paslode Pages: 20

360Xi

Brand: Paslode Pages: 12

F-350P

Brand: Paslode Pages: 32

502300

Brand: Paslode Pages: 32

901000

Brand: Paslode Pages: 40

FN 1665

Brand: Paslode Pages: 4

CR175C

Brand: Paslode Pages: 36

MHP36

Brand: Meister Pages: 166

FramePro 752XP

Brand: Senco Pages: 2

PHP 500 E3

Brand: Parkside Pages: 34