37

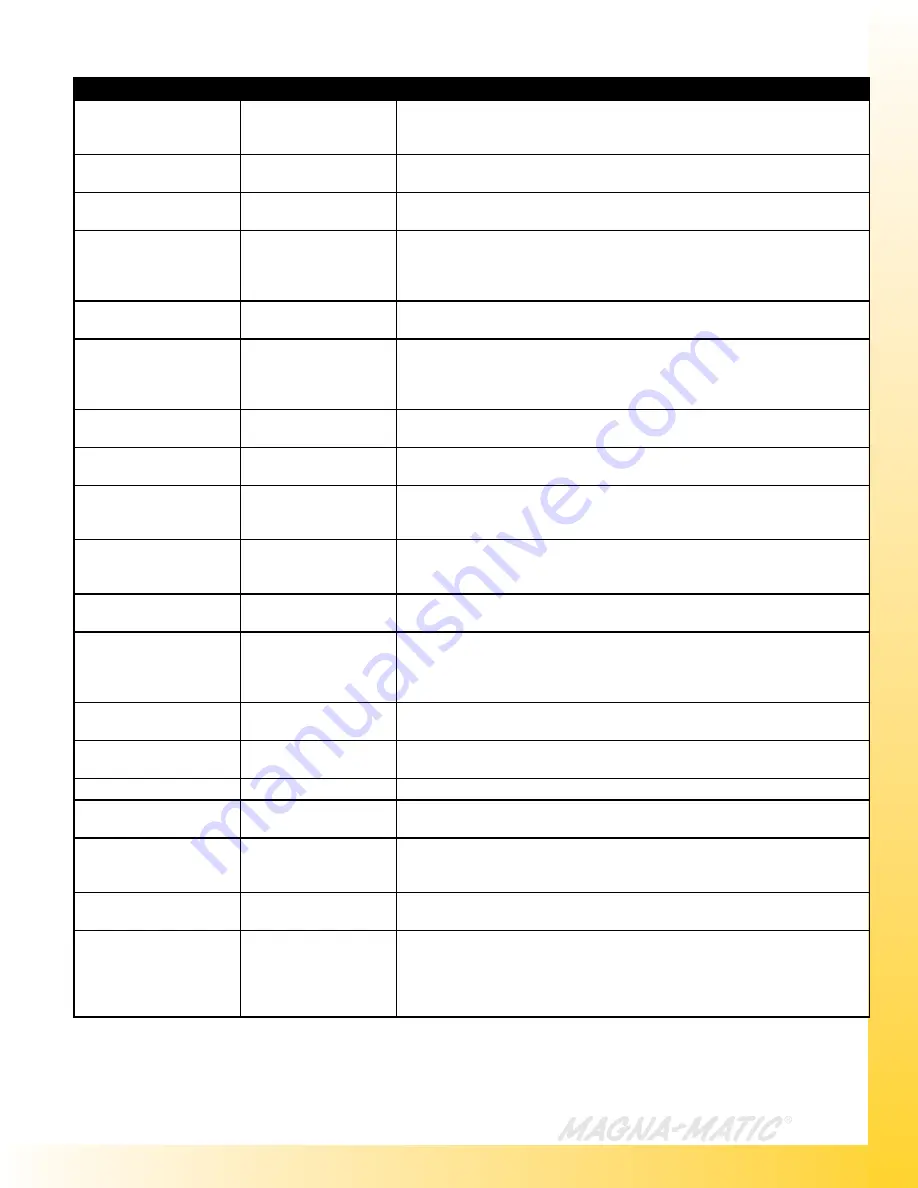

TROUBLESHOOTING

PROBLEM

CAUSE

SOLUTION

Motor fails to start

Fan guard bent/dam-

aged and contacting

fan.

Replace fan guard

Motor has been running,

then fails to start

Fuse or circuit breaker

tripped.

Replace fuse or reset the breaker.

Motor has been running,

then fails to start

Motor overloaded or

load jammed.

Inspect to see that the load is free. Verify amp draw of motor versus name

-

plate rating.

Motor has been running,

then fails to start

Capacitor may have

failed.

First discharge capacitor. To check capacitor, set volt-ohm meter to RX100

scale and touch its probes to capacitor terminals. If capacitor is OK, needle

will jump to zero ohms, and drift back to high. Steady zero ohms indicates a

short circuit; steady high ohms indicates an open circuit.

Motor has been running,

then fails to start

Starting switch has

failed.

See wiring diagram and connect the black wire from the motor and the black

wire from the cord to bypass the switch.

Motor runs but dies down Voltage drop

If voltage is less than 10% of the motor’s rating contact power company or

check if some other equipment is taking power away from the motor. If motor

is run using an extension cord, verify that this extension cord is properly

sized for motor’s current draw.

Motor takes too long to

accelerate

Defective capacitor

Test capacitor per previous instructions.

Motor takes too long to

accelerate

Bad bearings

Noisy or rough feeling bearings should be replaced.

Motor takes too long to

accelerate

Voltage too low.

Make sure that the voltage is within 10% of the motor’s nameplate rating.

If not, contact power company or check if some other equipment is taking

power away from the motor.

Motor overload protector

continually trips

Ambient temperature

too high.

Verify that the motor is getting enough air for proper cooling. Most motors

are designed to run in an ambient temperature of less than 40°C. (Note: A

properly operating motor may be hot to the touch.)

Start capacitors continu-

ously fail.

Voltage to motor is too

low.

Verify that voltage to the motor is within 10% of the nameplate value. If the

motor is rated 110-125 V, the deviation must be calculated from 125 V.

MAG-8200 is vibrating

Grinding wheel is out-

of-round

Dress the wheel and old lawn mower blade. Use a perfectly flat area, like

around the mounting hole. Place it in the sharpener like you would normal-

ly, and slowly apply pressure into the wheel. Do not go back and forth, just

apply even pressure, and let the wheel true itself.

MAG-8200 is vibrating

Bad motor bearings

Remove the grinding wheel, and run the MAG-8000. Inspect the motor shaft

and bearings.

MAG-8200 is vibrating

Loose pulleys or bear-

ing collars

Tighten set screws, locking agent should be used.

MAG-8200 is vibrating

Poor belt tension

Check idler pulley springs

MAG-8200 is vibrating

Bad drive shaft bear

-

ings

Check and replace the two flange bearings

MAG-8200 crank will not

adjust the wheel up or

down

Adjustment block

jammed

Inspect the guide rods for debris, or check if you are jammed at the top or

bottom of the adjustment.

Unable to remove grind-

ing wheel

Turning wrong direction

The arbor nut has left-handed threads. Turn clockwise to loosen. Use both

the arbor and spanner wrench.

Difficult to remove grind

-

ing wheel

Extremely tight, wheel

has not been changed

in a long time.

Using both the spanner and arbor wrenches, Allow the arbor wrench to

stop against the yellow body, Use a plastic hammer and tap the end of the

spanner wrench, imparting vibration will shock the nut loose. In extreme sit-

uations you can apply heat, only to the arbor nut. Last resort, you can break

the wheel off the arbor.