Page Number - 5

Form 403750

FlowMaster™ Rotary Driven Hydraulic Pump

Operation

All pumps are factory set at 300 PSIG (20.7 bar) working inlet

K\GUDXOLFSUHVVXUHZLWKDÀRZUDWHRI*30OPLQ

Do

not attempt to change the settings.

1. Shut off the material supply line valve.

2. Turn on the hydraulic pressure.

(QHUJL]HWKHVROHQRLG

On/Off

valve.

4. Prime the pump by slowly opening the shut-off lubricant

supply line valve. Make sure that all air has been

H[SHOOHGIURPWKHSXPSDQGHYHQOXEULFDQWÀRZLV

achieved.

7KHK\GUDXOLFÀRZUDWHDQGSUHVVXUHFRQWUROVHWWQJVDUH

factory preset and are not user adjustable.

Do not exceed maximum operating temperature of the

K\GUDXOLFÀXLG)&1HYHUDOORZWKHSXPSWRUXQ

dry of lubricant. A dry pump quickly speeds up, creating friction

heat, which can damage the seals. Monitor the supply

OXEULFDQWOHYHODQGUH¿OOZKHQQHFHVVDU\

Setting the Pump Manifold Pressure and

Flow Controls

7KHÀRZUDWHRI*30PLQDQGSUHVVXUHRI

PSIG (20.7 bar) are factory preset and are not adjustable.

Maintenance and Repair

Relieve pressure from the pump and supply lines before

servicing or repairing the pump, to reduce the risk of an injury

IURPLQMHFWLRQVSODVKLQJÀXLGRUPRYLQJSDUWV

Always use Lincoln Industrial parts for service and repair.

Crankcase Oil Service Interval Recommendations

Check the oil level after every 750 hours of machine operation,

or every month.

Change the oil after every 2,000 hours of machine operation or

every year.

Use SAE 10W30 motor oil in all units used in an ambient

temperature between 150 to -40°F. For ambient temperatures

between 50 to -70°F, use Mobil Arrow HFA Low Temperature

oil.

Oil level should be at dot on dipstick (middle of crankshaft)

XVLQJ:PRWRURLOR]

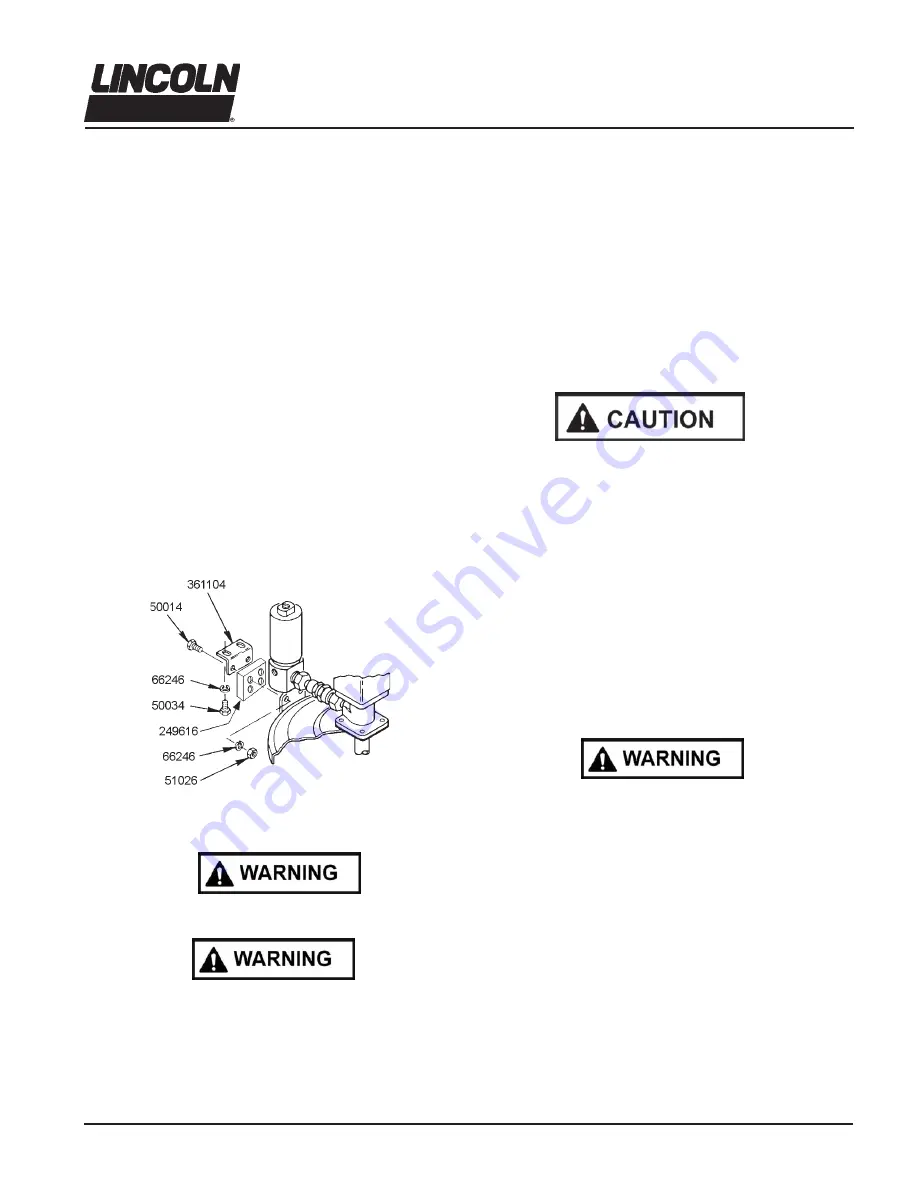

Installing the Pump

Typical installation is shown only as a guide for selecting and

installing system components. Contact your Lincoln

Industrial representative for assistance in designing a

V\VWHPWRVXLW\RXUVSHFL¿FQHHGV

The pump was tested in light weight oil which was left in to

protect the pump from corrosion. Flush the pump before con-

necting it to the system to prevent contamination of the grease

with residual oil.

7KHSXPSKDVÀRZDQGSUHVVXUHFRQWUROVLQWHJUDWHGLQWRWKH

manifold (37). A normally closed

ON/OFF

Solenoid Valve (35)

is also integrated into the manifold and will start or stop the

pump operation.

1. Mount the pump securely on the drum cover so that it

cannot move or vibrate during operation.

2. Attach hydraulic supply line to the

Inlet

and return line to

the

Tank

ports.

3. Connect material supply line to the pump outlet. Plug

the unused outlet on opposite side of the pump.

4. Install high pressure shut-off valve in the material supply

line. (Required)

5. Connect 24 VDC power supply to the solenoid valve (35).

See Illustration #1. Use connector plug (36) supplied

with the pump.

Mount the pump securely on the drum cover. Failure to do so

could result in personal injury and equipment damage.

* Included in Spacer Kit 272013

Illustration 4

Do not exceed 450 PSIG (32 bar) working hydraulic

pressure. Use high pressure components to reduce risk of

VHULRXVLQMXU\LQFOXGLQJÀXLGLQMHFWLRQDQGVSODVKLQJLQWKHH\HV

or on the skin. All accessories connected to the pump outlet

must have at least 5,000 PSIG (350 bar) minimum hydraulic

operating pressure. All accessories connected to the pump

inlet must have at least 3,500 PSIG (241 bar) minimum work-

ing pressure.