English

English

22

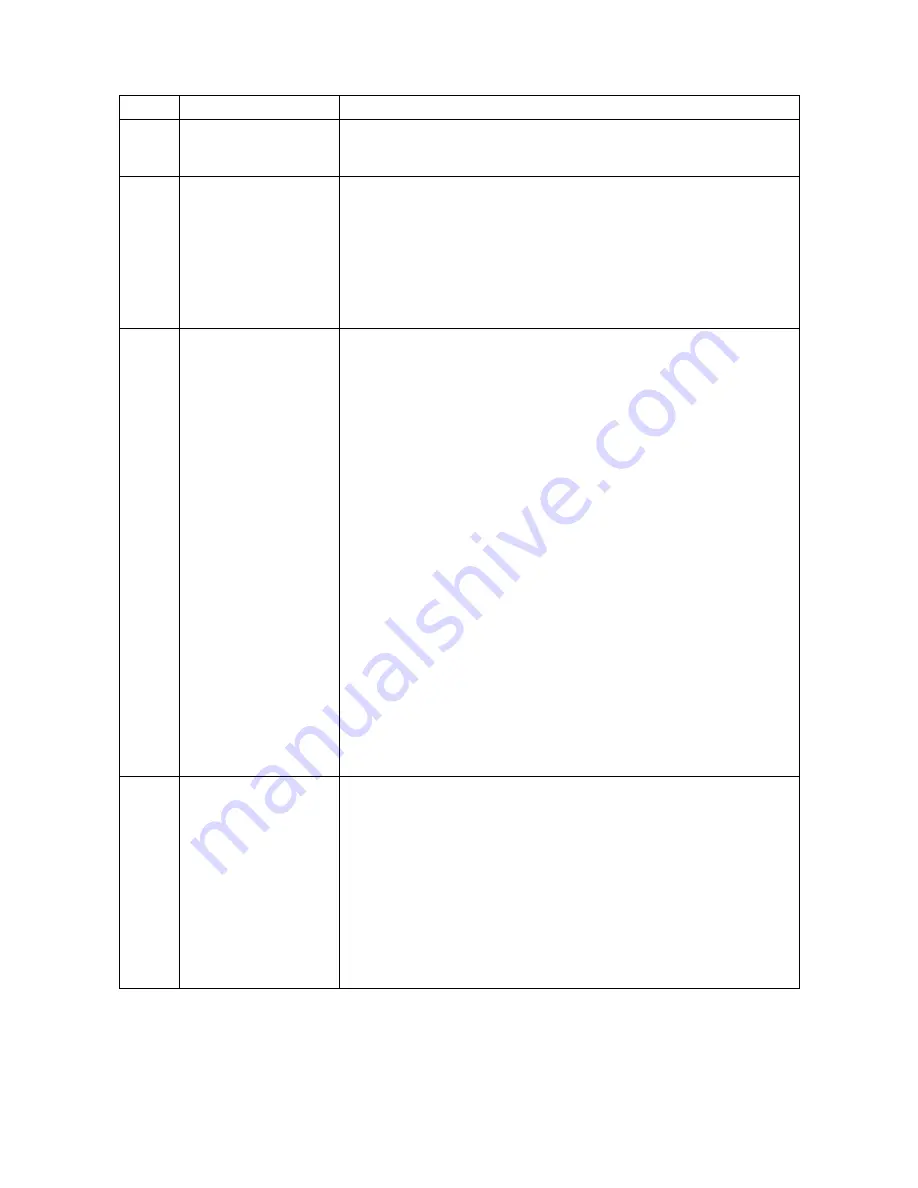

Table 11. The Configuration Parameters

P.0

The Menu Exit

Enables exit from menu

P.1

Wire Feed Speed (WFS)

units

Enables change WFS units:

•

"Metric" (factory default) = m/min;

•

"English" = in/min.

P.4

Recall Memory with

Trigger

(PF46 only)

This option allows a memory to be recalled by quickly pulling and releasing the

gun trigger:

•

"Enable" = Selecting memories 2 through 9 by quickly pulling and releasing

the gun trigger. To recall a memory with the gun trigger, quickly pull and

release the trigger the number of times that correspond to the memory

number. For example, to recall memory 3, quickly pull and release the

trigger 3 times. Trigger memory recall can only be performed when the

system is not welding.

•

"Disable" (factory default) = Memory selection is performed only by the

Panel Buttons.

P.5

Procedure Change

Method

(PF46 only)

This option selects how remote procedure selection (A/B) will be made. The

following methods can be used to remotely change the selected procedure:

••••

"External Switch" (factory default) = Dual Procedure selection may only be

performed by the Cross-switch gun or remote control.

••••

"Quick Trigger" = Allows switching between Procedure A and procedure B

while welding with 2-stroke mode. The Cross-switch gun or remote control

is required. To operate:

Select " WFS/Proced. A-B" in P.25 to set up parameters for A and B

procedures.

Start the weld by pulling the gun trigger. The system will weld with

procedure A settings.

While welding, quickly release and then pull the gun trigger. The

system will switch to procedure B settings. Repeat to switch back to

procedure A settings. The procedure can be changed as many times

as needed during the weld.

Release the trigger to stop welding. When the next weld is made, the

system will start again with procedure A.

••••

"IntegralTrigProc" = Allows switching between Procedure A and procedure

B while welding with 4-stroke mode. When in 2-step, the system operates

identical to the External Switch selection. To operate in 4-step:

Select " WFS/Proced. A-B" in P.25 to set up parameters for A and B

procedures.

Start the weld by pulling the gun trigger. The system will weld with

procedure A settings.

While welding, quickly release and then pull the gun trigger. The

system will switch to procedure B settings. Repeat to switch back to

procedure A settings. The procedure can be changed as many times

as needed during the weld.

Release the trigger to stop welding. When the next weld is made, the

system will start again with procedure A.

P.7

Gun Offset Adjustment

This option adjusts the wire feed speed calibration of the pull motor of a push-

pull gun. This should only be performed when other possible corrections do not

solve any push-pull feeding problems. An rpm meter is required to perform the

pull gun motor offset calibration. To perform the calibration procedure do the

following:

1. Release the pressure arm on both the pull and push wire drives.

2. Set the wire feed speed to 200 ipm.

3. Remove wire from the pull wire drive.

4. Hold an rpm meter to the drive roll in the pull gun.

5. Pull the trigger on the push-pull gun.

6. Measure the rpm of the pull motor. The rpm should be between 115

and 125 rpm. If necessary, decrease the calibration setting to slow the

pull motor, or increase the calibration setting to speed up the motor.

•

The calibration range is -30 to +30, with 0 as the default value.