English

English

42

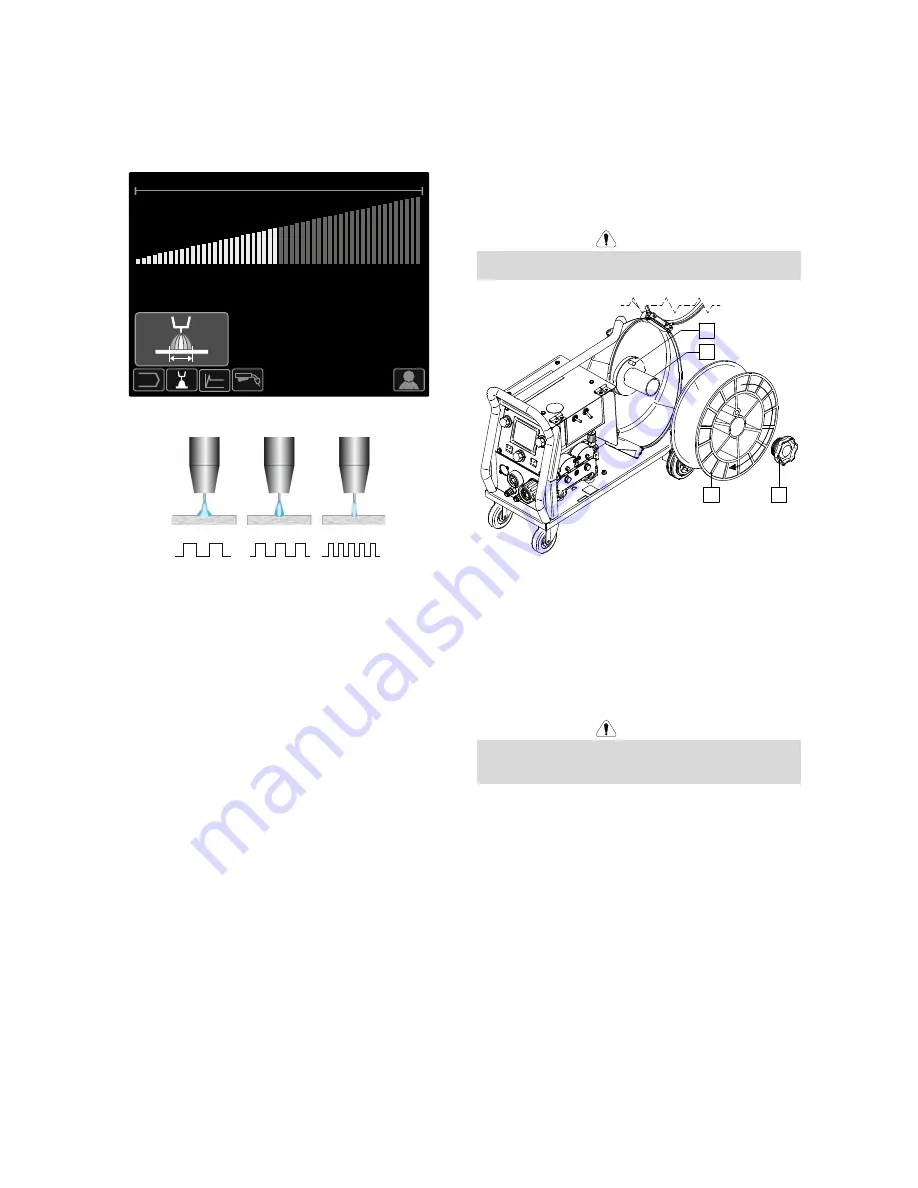

UltimArc™

– for pulse welding adjusts the focus or

shape of the arc. In consequence of increasing

UltimArc™ Control value the arc is tight, stiff for high

speed sheet metal welding.

••••

Adjust range: from -10 to +10

••••

Factory default, UltimArc™ is OFF.

-10.0

10.0

OFF

OFF

A

Figure 90

1

2

3

Figure 91

1. UltimArc™ Control "-10.0": Low Frequency, Wide.

2. UltimArc™ Control OFF: Medium Frequency and

Width.

3. UltimArc™ Control "+10.0": High Frequency,

Focused.

Wire Spool Loading

Wire spool type S300 and BS300 can be installed on the

wire spool support without adapter.

Wire spool type S200, B300 or Readi-Reel

®

can be

installed, but the applicable adapter must be purchased.

The applicable adapter can be purchased separately

(see "Accessories" chapter).

Wire Spool Type S300 & BS300 Loading

WARNING

Turn the input power OFF at the welding power source

before installation or changing a wire spool.

28

29

30

31

Figure 92

••••

Turn the input power OFF.

••••

Open the spool wire case.

••••

Unscrew the Locking Nut [28] and remove it from the

Spindle [30].

••••

Place the spool type S300 or BS300 [29] on the

Spindle [30] making certain the Spindle Brake Pin

[31] is put in the hole in back side of spool type S300

or SB300.

WARNING

Position the spool type S300 or SB300 so that it will

rotate in a direction when feeding so as to be de-reeled

from bottom of the spool.

••••

Re-install the locking nut [28]. Make sure that the

locking nut is tightened.