English

English

4

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the

correct shielding gas for the process used and properly operating regulators designed for the gas and

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

MOVING PARTS ARE DANGEROUS: There are moving mechanical parts in this machine, which can

cause serious injury. Keep your hands, body and clothing away from those parts during machine

starting, operating and servicing.

The manufacturer reserves the right to make changes and/or improvements in design without upgrade at the same time

the operator’s manual.

Introduction

PF44

and

PF46

are digital wire feeders which have been

designed to work with all Lincoln Electric power sources

using ArcLink

®

protocol to communication.

Digital wire feeders allow the welding:

•

GMAW (MIG/MAG)

•

FCAW-GS / FCAW-SS

•

SMAW (MMA)

•

GTAW (arc ignition using lift TIG)

Recommended equipment, which can be bought by

user, was mentioned in the chapter "Accessories".

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

Location and Environment

This machine will operate in harsh environments.

However, it is important that simple preventative

measures are followed to assure long life and reliable

operation.

•

Do not place or operate this machine on a surface

with an incline greater than 15° from horizontal.

•

Do not use this machine for pipe thawing.

•

This machine must be located where there is free

circulation of clean air without restrictions for air

movement.

•

Dirt and dust that can be drawn into the machine

should be kept to a minimum.

•

This machine has a protection rating of IP23. Keep

it dry when possible and do not place it on wet

ground or in puddles.

•

Locate the machine away from radio controlled

machinery. Normal operation may adversely affect

the operation of nearby radio controlled machinery,

which may result in injury or equipment damage.

Read the section on electromagnetic compatibility in

this manual.

•

Do not operate in areas with an ambient

temperature greater than 40°C.

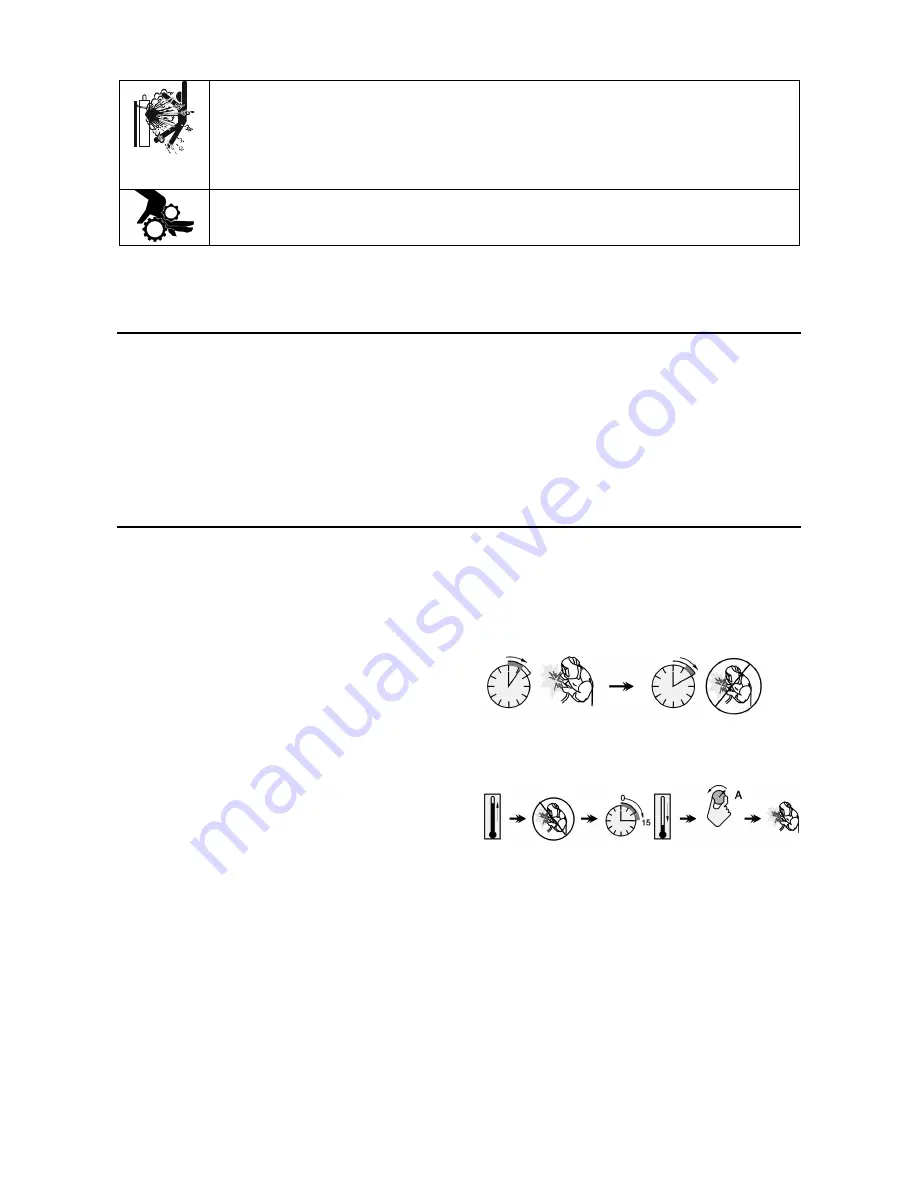

Duty cycle and Overheating

The duty cycle of a welding machine is the percentage

of time in a 10 minute cycle at which the welder can

operate the machine at rated welding current.

Example: 60% duty cycle

Welding for 6 minutes.

Break for 4 minutes.

Excessive extension of the duty cycle will cause the

thermal protection circuit to activate.

Minutes

or decrease

Duty Cycle

Input Supply Connection

Check the input voltage, phase, and frequency of the

power source that will be connected to this wire feeder.

The allowable input voltage source is indicated on the

rating plate of the wire feeder. Verify the connection of

grounding wires from the power source to the input

source.