Location Considerations

5

2.0

L

OCATION

C

ONSIDERATIONS

The STS2/PDU should be placed in a clean, cool and dry location. The 250A unit without an output

cabinet requires only front access for installation and maintenance. Both front and side access are

required for installation and maintenance of 400-800A units and 250A units with output cabinet. The

output cabinet comes factory installed or either the right or left side depending on how it was ordered.

It cannot be moved from one side to the other in the field.

Adequate space is required above the unit for conduit (if configured as such) and cooling air flow. This

section provides specific information for these considerations.

The unit is designed with top and bottom cable terminations to allow maximum flexibility in its

installation. Units with output inline panelboards are bottom exit only. If bottom cable entry and exit

is used, sufficient cable bending space must be provided by a raised floor or a floor stand.

For dimensions of each unit, see

Figures 7

through

22

. If your unit is equipped with an optional key

lockout switch, see

Figures 13

through

21

for the location of that switch.

2.1

Recommended Minimum Service Clearances

The recommended service clearances are at the front and side, if equipped with output cabinet. The

minimum service clearance required by the National Electrical Code (NEC) Article 110-26 is

36 in. (91cm) for units with voltages up to 150V to ground and 42 in. (107cm) for units with voltages

over 150V to ground. Clearance of at least 18 in. (46cm) is required above the unit for cooling air flow.

2.2

Heat Output

The unit produces minimal heat during normal operation.

2.3

Operating Environment

The unit is designed to be installed indoors where the ambient air temperature is in the range of

32° to 104°F (0°C - 40°C) with a relative humidity of 0% to 95% non-condensing, up to an altitude of

4000 feet (1200 meters).

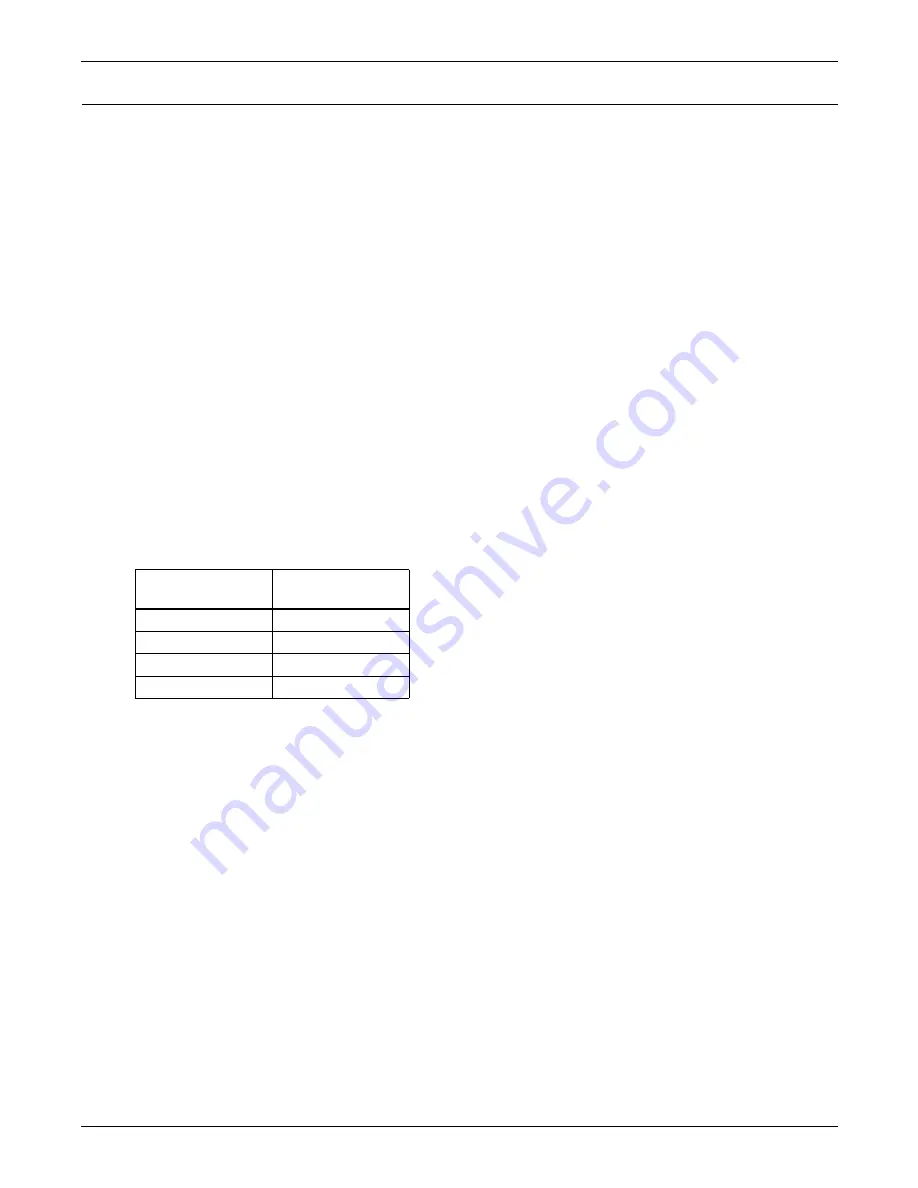

Table 2

Heat output

Switch Size

Heat Output

BTU/Hr (kW)

250A

12,590 (3.69)

400A

20,140 (5.90)

600A

30,200 (8.85)

800A

40,270 (11.80)

Summary of Contents for PDUTM

Page 25: ...Installation Drawings 17 7 0 INSTALLATION DRAWINGS Figure 7 Outline drawing 250A STS2 PDU ...

Page 42: ...Installation Drawings 34 Figure 24 Electrical field connections 250A STS2 PDU input with CB3 ...

Page 46: ...Installation Drawings 38 Figure 28 Electrical field connections 800A STS2 PDU input with CB3 ...

Page 63: ...Installation Drawings 55 Figure 45 Control wiring 800A STS2 PDU left side distribution ...

Page 64: ...Installation Drawings 56 Figure 46 Control wiring 800A STS2 PDU right side distribution ...

Page 65: ...Installation Drawings 57 Figure 47 Control connection location 250A STS2 PDU ...

Page 66: ...Installation Drawings 58 Figure 48 Control connection location 400 800A STS2 PDU ...

Page 68: ...Installation Drawings 60 Figure 50 Control wiring for the programmable relay board option ...

Page 69: ...Installation Drawings 61 Figure 51 Control wiring for the input contact isolator board option ...

Page 70: ...Installation Drawings 62 Figure 52 Control wiring for comms board ...

Page 71: ...Installation Drawings 63 Figure 53 Control wiring for the internal modem option ...

Page 72: ...Installation Drawings 64 Figure 54 Control wiring for the Network Interface Card NIC option ...

Page 73: ...Installation Drawings 65 Figure 55 Control wiring for the RS 232 Port ...

Page 74: ...Installation Drawings 66 Figure 56 Control wiring for remote source selection option ...

Page 75: ...Installation Drawings 67 Figure 57 Color LCD touch screen display ...

Page 155: ......