Page 7

Blower Operation and Adjustments

A-Three Scroll Compressor Voltage Phasing

Three phase scroll compressors must be phased

sequentially to ensure correct compressor and blower

rotation and operation. Compressor and blower are

wired in phase at the factory. Power wires are

color-coded as follows: line 1-red, line 2-yellow, line

3-blue.

1- Observe suction and discharge pressures and

blower rotation on unit start-up.

If pressure differential is not observed or blower rotation is

not correct:

2- Suction pressure must drop, discharge pressure

must rise, and blower rotation must match rotation

marking.

3- Disconnect all remote electrical power supplies.

4- Reverse any two field-installed wires connected to

the line side of K3, TB2 or F4. Do not reverse wires

at blower contactor or compressors.

5- Make sure the connections are tight.

Discharge and suction pressures should operate at

their normal start‐up ranges.

B-Blower Operation

Initiate blower demand at thermostat according to

instructions provided with thermostat. Unit will cycle on

thermostat demand. The following steps apply to

applications using a typical electro-mechanical

thermostat.

1- Blower operation is manually set at the thermostat

subbase fan switch. With fan switch in

ON

position,

blowers will operate continuously.

2- With fan switch in

AUTO

position, the blowers will

cycle with demand. Blowers and entire unit will be off

when system switch is in

OFF

position.

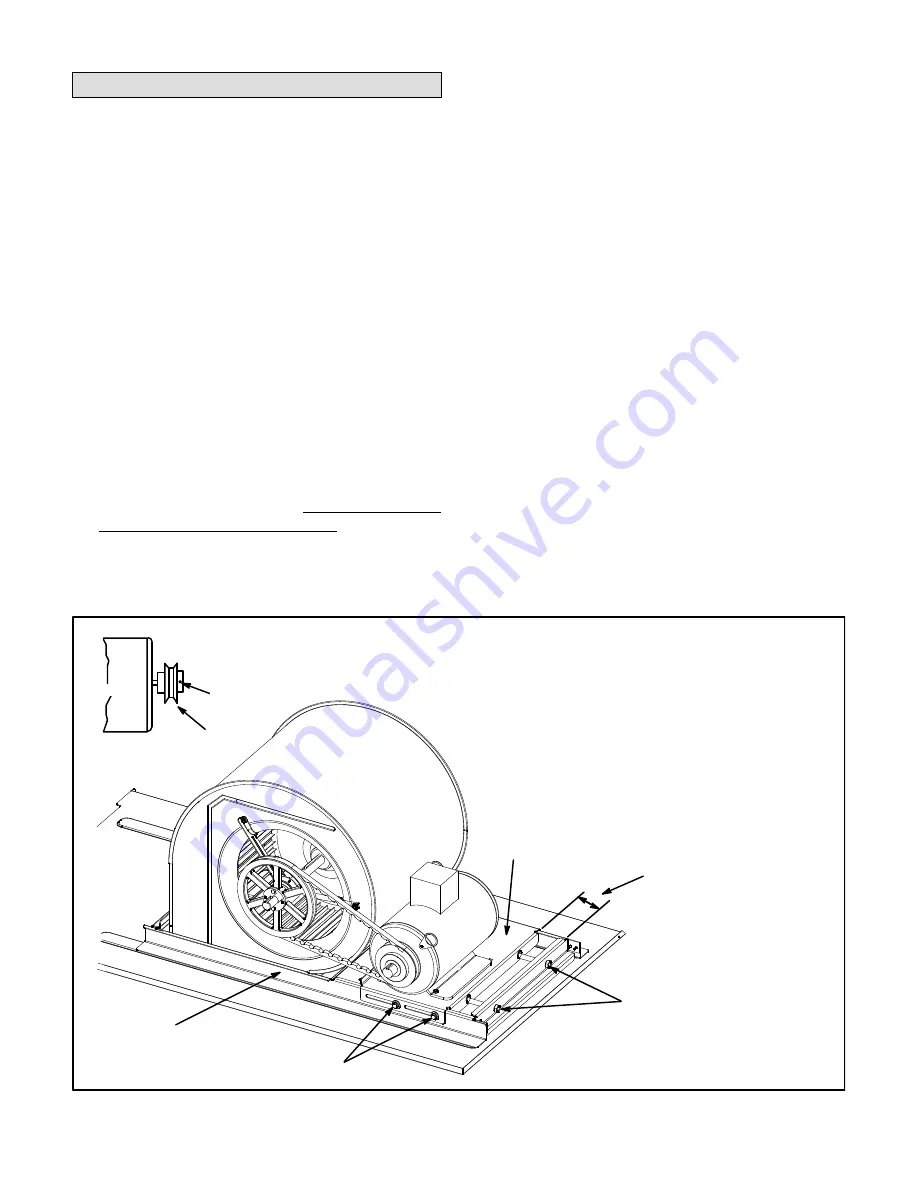

C-Blower Access

The blower assembly is secured to a sliding frame which

allows the blower motor to be pulled out of the unit. See

figure 6.

1- Loosen the reusable wire tie which secures the

blower wiring to the blower motor mounting plate.

2- Remove and retain screws on either side of sliding

frame. Pull frame toward outside of unit.

3- Slide frame back into original position when finished

servicing. Reattach the blower wiring in the previous

location on the blower motor base using the wire tie.

4- Replace retained screws on either side of the sliding

frame.

STANDARD BLOWER ASSEMBLY

TO INCREASE BELT TENSION

1- Loosen four bolts securing motor mounting base

to frame.

2- Turn adjusting bolt to the right, or clockwise, to

move the motor away from the blower housing.

IMPORTANT - Gap between end of frame and motor

mounting base should be equal at both ends, i.e. par

allel along gap.

3- Tighten four bolts securing motor mounting base

to frame.

4- Relieve tension on two adjusting bolts.

FIGURE 6

PULLEY

MOTOR

SIDE VIEW

ALLEN

SCREW

BELT ADJUSTING BOLTS

- TURN CLOCKWISE

TO TIGHTEN BELT

MOTOR

MOUNTING

BASE

LOOSEN BEFORE

ADJUSTING BELT TENSION

(TWO EACH SIDE)

MOTOR

BLOWER

HOUSING

BLOWER

FRAME

GAP BETWEEN EDGES SHOULD

BE PARALLEL ON BOTH ENDS

BEFORE TIGHTENING MOTOR

MOUNTING BASE IN PLACE