Page 4

# 504,910M

using a proper conduit fitting. Units are approved for

use only with copper conductors. 24V Class II circuit

connections are made in the low voltage junction box.

Refer to Figure 7 on page 15 for field wiring diagram

(wiring diagram also found inside unit control box

cover).

3. Install room thermostat on an inside wall that is not

subject to drafts, direct sunshine, or other heat

sources.

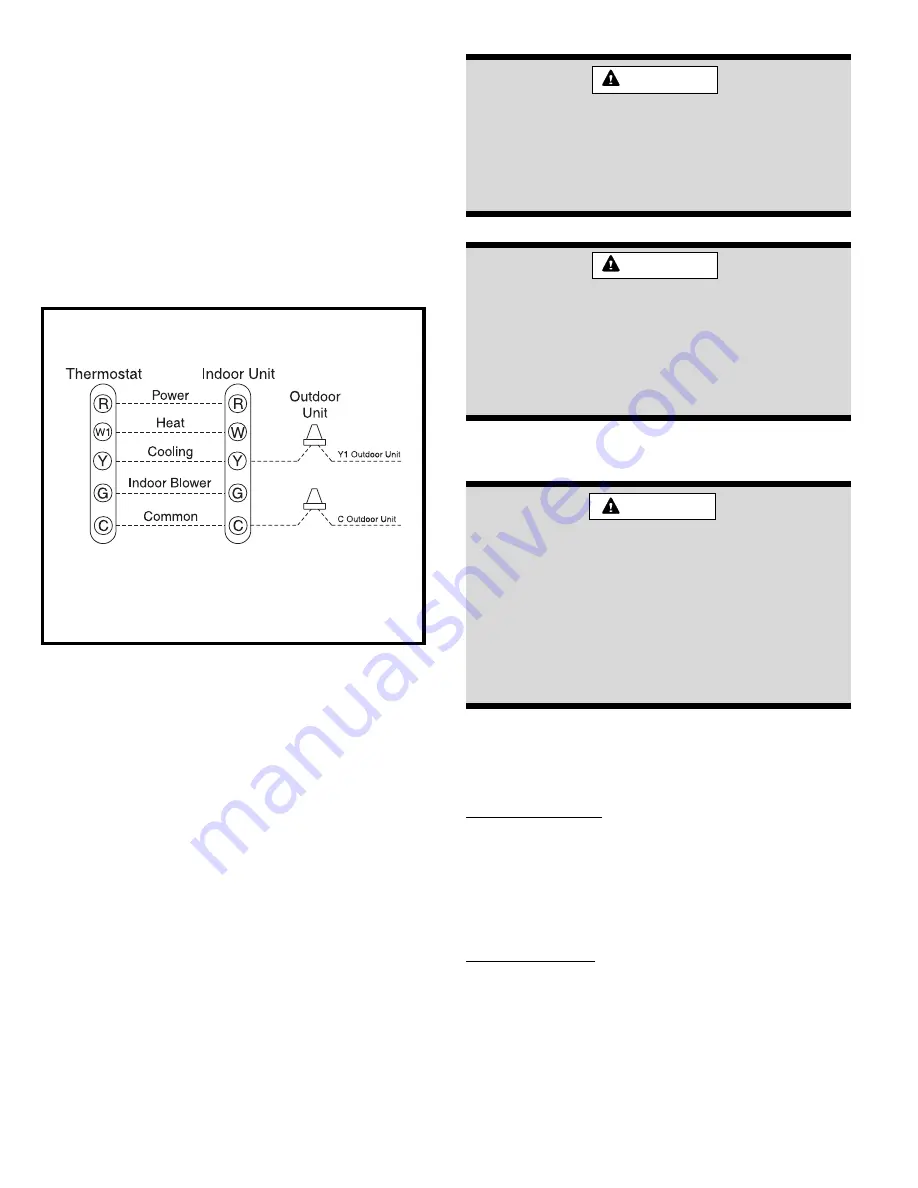

4. Install low voltage wiring from outdoor to indoor unit

and from thermostat to indoor unit (see Figure 2).

Thermostat Designations

Figure 2

See unit wiring diagram for power supply connections.

If the indoor unit is not equipped with a blower relay,

one must be field-supplied and installed.

Refrigerant Piping

If the SCU12M unit is being installed with a new indoor

coil and line set, the refrigerant connections should be

made as outlined in the section found on page 6 entitled

Plumbing Connections Using New Indoor Coil and

Line Set

. If an existing line set and/or indoor coil will be

used to complete the system, refer to the following section

entitled

Flushing Existing Line Set and Indoor Coil

.

If this unit is being matched with an approved line set

or indoor coil which was previously charged with R22

refrigerant, the line set and coil must be flushed prior to

installation. If the unit is being used with an existing

indoor coil which was equipped with a liquid line which

served as a metering device (RFCI), the liquid line must

be replaced prior to the installation of the SCU12M unit.

Field refrigerant piping consists of liquid and suction lines

from the outdoor unit (sweat connections) to the indoor

coil (flare or sweat connections).

Flushing Existing Line Set and Indoor Coil

Polyol ester (POE) oils used with R410A

refrigerant absorb moisture very quickly. It is

very important that the refrigerant system be

kept closed as much as possible. DO NOT

remove line set caps or service valve stub

caps until ready to make connections.

WARNING

Before opening any system, make sure the

pressure in the system is brought to and

remains at atmospheric pressure. Failure to

comply can result in system damage and/or

personal injury.

WARNING

When flushing existing line set and/or indoor

coil, be sure to empty all existing traps. Re-

sidual mineral oil can act as an insulator,

preventing proper heat transfer. It can also

clog the thermal expansion valve, reducing

system performance and capacity. Failure to

properly flush the system as explained in

these instructions will void the warranty.

CAUTION

This procedure should not be performed on systems

which contain contaminants, such as compressor

burn out.

Required Equipment (see Figure 3)

The following equipment is needed to flush the existing

line set and indoor coil: Two clean R22 recovery bottles,

an oil-less recovery machine with a pump down feature,

and two sets of gauges (one for use with R22 and one for

use with R410A).

Flushing Procedure

IMPORTANT:

The line set and/or indoor coil must be

flushed with at least the same amount of refrigerant that

previously charged the system. Check the charge in the

flushing cylinder before flushing the unit.

1. Remove existing R22 refrigerant using the appropriate

procedure.