Technical description

Part 1 • Page 5-1

Part 1 – Operating Instructions

Rev. 4.00 December 2014

Software version 1.04

EcoRO Dia I/II (HT)

Part 1 • Chapt

er 5

5.

Technical description

The

Aquaboss

®

EcoRO Dia I/II (HT) provides the operator with a geared to consumption reverse osmosis

system. A 4-line LCD plain text display allows all operating parameters to be called up and monitored at

any time.

A special flushing and disinfection program developed for compact systems with the integrated

Aquaboss

®

impulse back washing system ensures maximum dialysis water hygiene.

An innovative logical control system makes high water yield possible even under unfavourable raw water

conditions. In this respect, the raw water consumption depends solely on the purest water requirement of

the end operator.

A menu-guided plain text display enables the operator to monitor all production parameters and system

functions including the disinfection mode in an individual and reproducible way.

Special advantages

•

Operator-friendly operation thanks to the menu-guided control system with plain text display

•

Low water consumption including rinsing water for

Aquaboss

®

softener and standstill rinsing

•

Shut-down and standstill rinsing with leakage monitoring during standby mode

•

Membrane blockage protection using

Aquaboss

®

impulse back washing

•

Optional impulse shear force rinsing

•

Durable stainless steel design

•

Mains separation / unhindered input in accordance with national safety standards

•

Option: Hot sanitation of the 1st and 2nd membrane stage (only for EcoRO Dia I/II (HT))

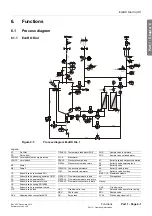

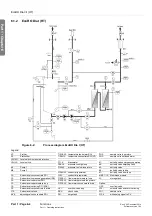

5.1

How it works

The treatment of water (for requirement see

part 2, chapter 7) by a reverse osmosis system results

in purified water (permeate) which is characterized by very low values for the chemicals within the water.

The separation rate of the undesired chemical contents is over 95%!

The permeate quality for water for diluting haemodialysis concentrates is defined Standard

AAMI/ANSI/ISO 23500:2011 (see

The EcoRO Dia I/II (HT) works on the reverse osmosis principle. Reverse osmosis describes a process

involving a pressure-operated cross-filtration system. The water flows under high pressure (up to max.

22 bar / 319 psi) tangentially over a semi-permeable membrane. As is the case with normal filtration, the

system is cleaned by allowing one component (water) of the mixture to be separated to pass through the

membrane with almost no hindrance, while the other components (dissolved and undissolved water con-

tents) are held back to a greater or lesser extent and leave the filtration unit in the concentrate flow. This is

a purely physical separation process in the molecular range which does not change the components being

separated either chemically, biologically or thermally.

A polyamide membrane (nonporous polymer membrane) is used. The material transport through such

a membrane type can be described in high accordance with experimental results on the basis of the

solution diffusion model. This model views the polymer membrane as a real fluid in which the permeands

dissolve and are diffusively transported along the gradient of their propelling force.