18

Checking the Normal PCB Operation

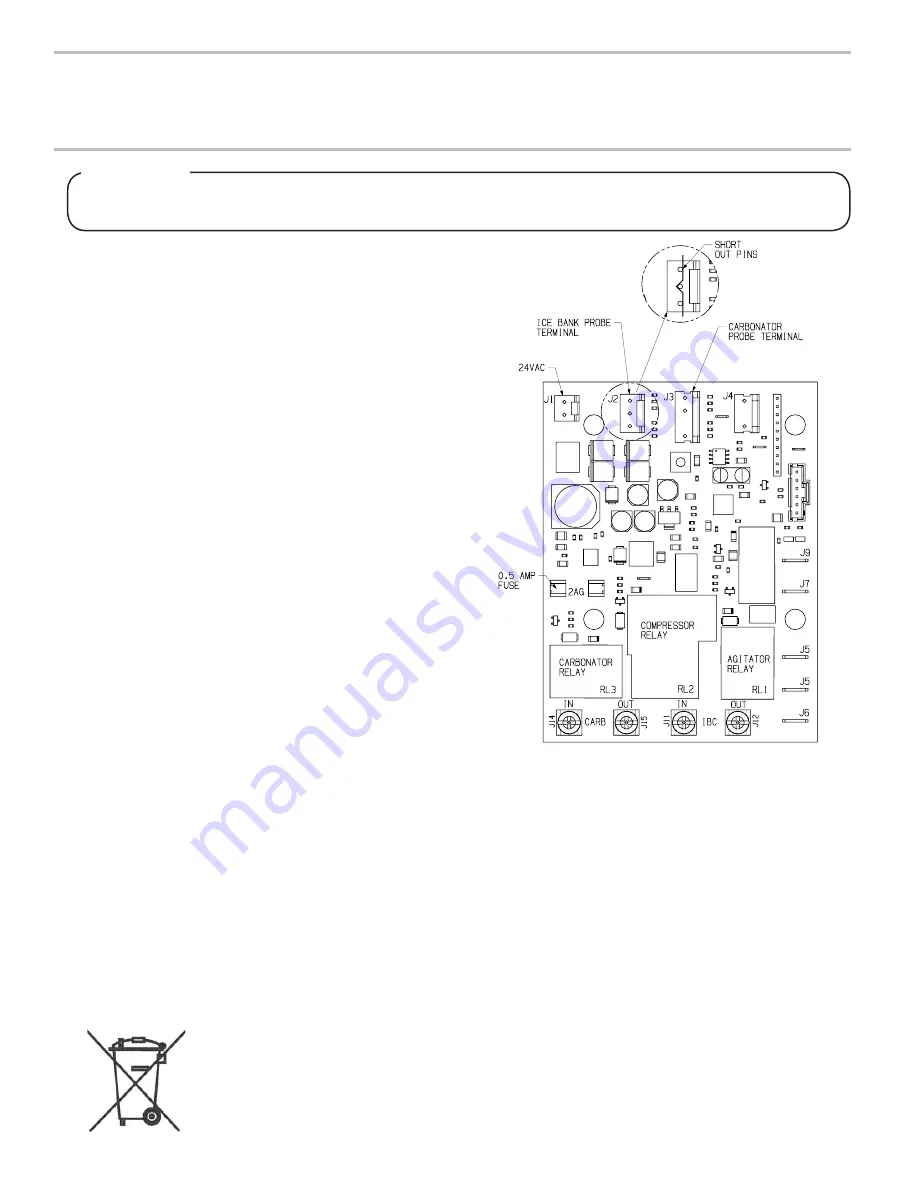

THE ELECTRONIC ICE BANK CONTROL (EIBC)

Terminal block has AC line voltage and, when servicing the unit, should be covered with tape. Tape should cover bare

electrical connections to prevent electrical shock.

!

WARNING

1. Turn power OFF or insure that power has been

disconnected from dispenser

2. Check condition of 0.5 amp fuse at location shown in di-

agram to the right. If fuse is blown, trace cause of short

in valve wire harness and associated 24 VAC lines and

replace fuse. If fuse is good, continue with next step.

3. Disconnect leads from the terminal block that connect to the

PCB, noting their specific location for reconnection.

4. Disconnect both the Ice Bank probe (J2) and the

Carbonator probe (J3) (if equipped) connections from

board.

5. Use a short copper wire, paper clip, or other means to short

the Ice Bank probe terminals (J2) on the PCB by touching

all three (3) pins together.

6. Set Ohm test meter to measure continuity.

7. Reconnect power or turn dispenser ON.

8. Observe time and check continuity of the PCB screw lug

connections:

9. Turn electrical power OFF for 15 seconds and then back ON again to reset Carbonator timer. Again, measure continuity of the

PCB screw lug connections

•

Terminal 3 to 4 (Carbonator): During the first 2.5 to

3.5 minutes there should be continuity. After 2.5 to 3.5

minutes, there should be NO continuity.

•

Terminal 2 to 1 (Compressor): During first 4 to 6

minutes, there should be NO continuity. After 4 to 6

minutes, there should be continuity. There should be

NO continuity from 2 to 1.

•

You should be able to hear a “click” sound of the relay

closing when the time delay ends.

•

Terminal 3 to 4: There should be continuity. Use a short copper wire, paper clip, or other means to short the Carbonator

probe terminals (J3) on the PCB by touching all three (3) pins together. This should be done before the 2.5 to 3.5 minute

time limit has elapsed. Measure the continuity again between Terminal 3 to 4: There should be

NO

continuity.

10. If all the above work as noted, then the board is functioning properly. Remove tape and reconnect board. If any non-conformities

are found, the PCB must be replaced (PN 52-1423/01).

To prevent possible harm to the environment from improper disposal, recycle the unit

by locating an authorized recycler or contact the retailer where the product was purchased.

Comply with local regulations regarding disposal of the refrigerant and insulation.

Dispenser Disposal

Summary of Contents for CED-04

Page 19: ...19 INTENTIONALLY LEFT BLANK...

Page 23: ...23 Wiring Diagram 115 Volt...