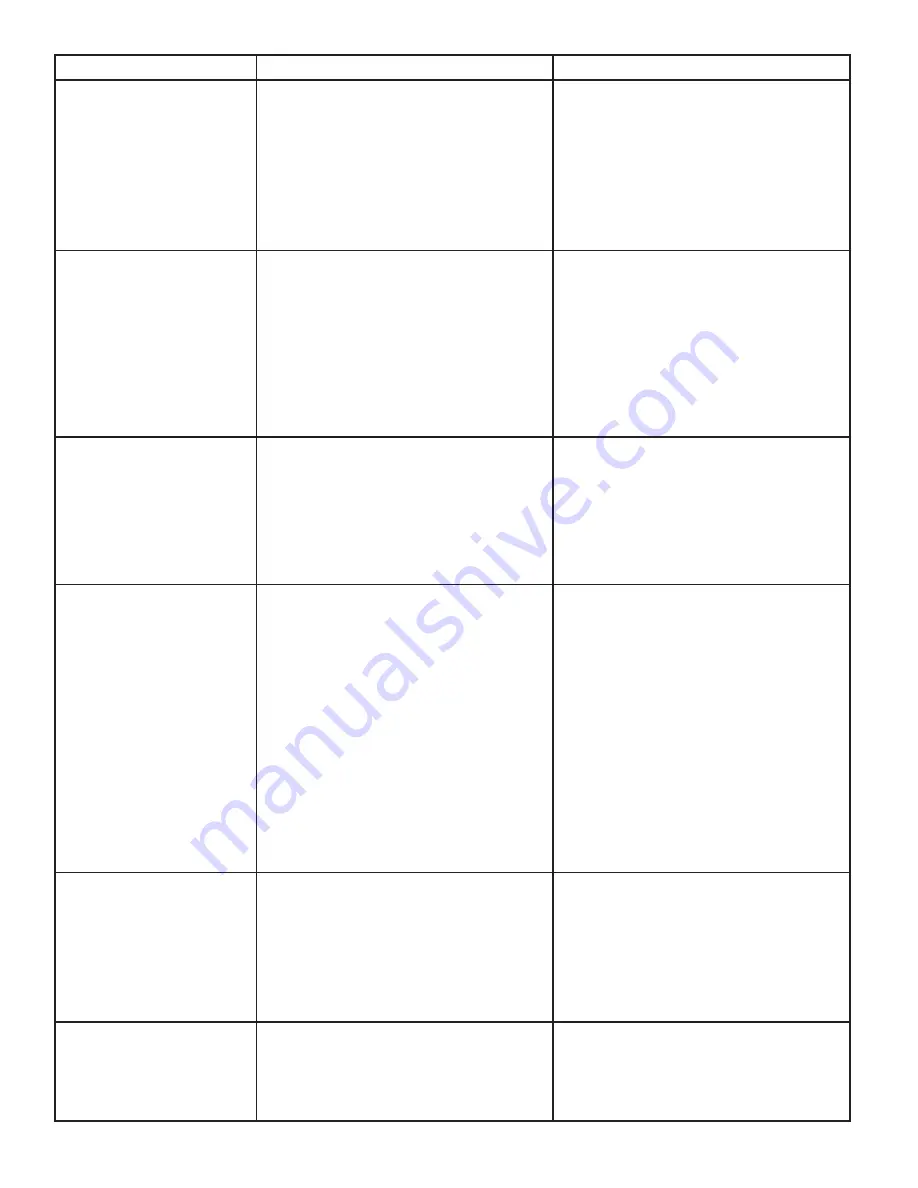

16

TROUBLE

CAUSE

REMEDY

Compressor does not start (no

hum), but gas cooler fan motor

runs.

1. Compressor relay, capacitors, or overload

protectors malfunctioning.

2.

Inadequate voltage.

3. Incorrect wiring.

4. Compressor malfunctioning.

1. Replace compressor relay, capacitors, or

overload protector.

2. Measure voltage across commom and run

terminal on compressor. Voltage must not

drop below 90% of rated voltage.

3. Refer to wiring diagram and correct.

4.

Have the unit repaired by a qualified

service technician.

Compressor does not start but

hums.

1.

Inadequate voltage.

2. Incorrect wiring.

3. Start capacitor or relay malfunctioning.

4. Compressor malfunctioning.

1. Measure voltage across common and run

terminal on compressor. Voltage must not

drop below 90% of rated voltage.

2. Refer to wiring diagram and correct.

3. Replace start capacitor or relay. Be sure

to use correct rating. Failure to use correct

rating will cause compressor failure.

4.

Have the unit repaired by a qualified

service technician.

Compressor starts but does not

switch off start winding (will run

for only a few seconds before

internal overload switches

before internal overload

switches compressor off).

1.

Inadequate voltage.

2. Incorrect wiring.

3. Starting relay malfunctioning.

1. Measure voltage across common and run

terminal on compressor. Voltage must not

drop below 90% of rated voltage.

2. Refer to wiring diagram and correct.

3. Replace starting relay. Be sure to use

correct relay. Failure to use correct relay

will cause compressor failure.

Compressor starts and runs

a short time but shuts off on

overload.

1. Dirty condenser.

2.

Insufficient or blocked air flow.

3.

Inadequate voltage.

4. Incorrect wiring.

5. Defective condenser fan motor.

6. Refrigerant leak.

7. Compressor malfunctioning.

1. Clean the condenser.

2. Remove all obstruction and allow for

minimum clearances of 8 inches (203 mm)

over top.

3. Measure voltage across common and run

terminal on compressor. Voltage must not

drop below 90% of rated voltage.

4. Refer to wiring diagram and correct.

5.

Have the unit repaired by a qualified

service technician.

6.

Have the unit repaired by a qualified

service technician.

7.

Have the unit repaired by a qualified

service technician.

Compressor runs normally, but

water line is frozen.

1. Low water level in water bath.

2. Syrup in water bath.

3. Water cage is out of position.

4. Low refrigerant charge or slow refrigerant

leak.

1. Add water to water bath until water runs

out of overflow into drip tray.

2. Drain water from water bath and refill with

clean water.

3. Reposition water cage.

4.

Have the unit repaired by a qualified

service technician.

Compressor cycles on and off

frequently during the initial

pulldown and/or normal

operations.

1. PCB malfunctioning

2. Defective probe.

3. Weak overload or pressure switch.

1. See page 18.

2. Replace probe.

3.

Have the unit repaired by a qualified

service technician.

Summary of Contents for CED-04

Page 19: ...19 INTENTIONALLY LEFT BLANK...

Page 23: ...23 Wiring Diagram 115 Volt...