HeLPFuL HIntS

1. Use only dry, seasoned wood that has been cut

and split and placed under cover to dry for 6 to 9

months. (25-30% moisture content). Hardwood

should be one year drying time to be seasoned.

2. Use 16” wood lengths. (Fire chamber is 18 ½”)

3. Never burn less than two (3-piece minimum, tri-

angle shaped) rows of wood, regardless of their

size. The reason for this that each log gives off

its heat to the adjoining log to sustain continuous

combustion.

4.

Do not start a fire in a cold fire chamber with ex-

cessive amounts of paper and kindling, because

the chimney is cold and lacks sufficient draft

causing the “chugging” effect that could produce

some puffing of smoke through your pipe joints.

5. Keep the front one-half (9”) of the fire chamber

free of grey ashes.

6. Always rake the hot coals forward from the back,

but leaving a space of 1 to 2 inches between the

front inside face and the hot coals.

7. Always burn down the coals if they are exces-

sive. When the coals have been raked forward,

the back half of the fire chamber floor should be

free of any hot coals. If the logs are added when

there are hot coals in the back, the logs will ignite

and burn from the back to the front, just opposite

from what it should be.

8. Whenever wood lengths are added to the fire

chamber, when there are some hot coals, make

sure that the front of the logs are in contact with

the hot coals so that the logs ignite.

9. Empty the ash pan when the fire chamber is cold

and dispose of them as recommended on page

10.

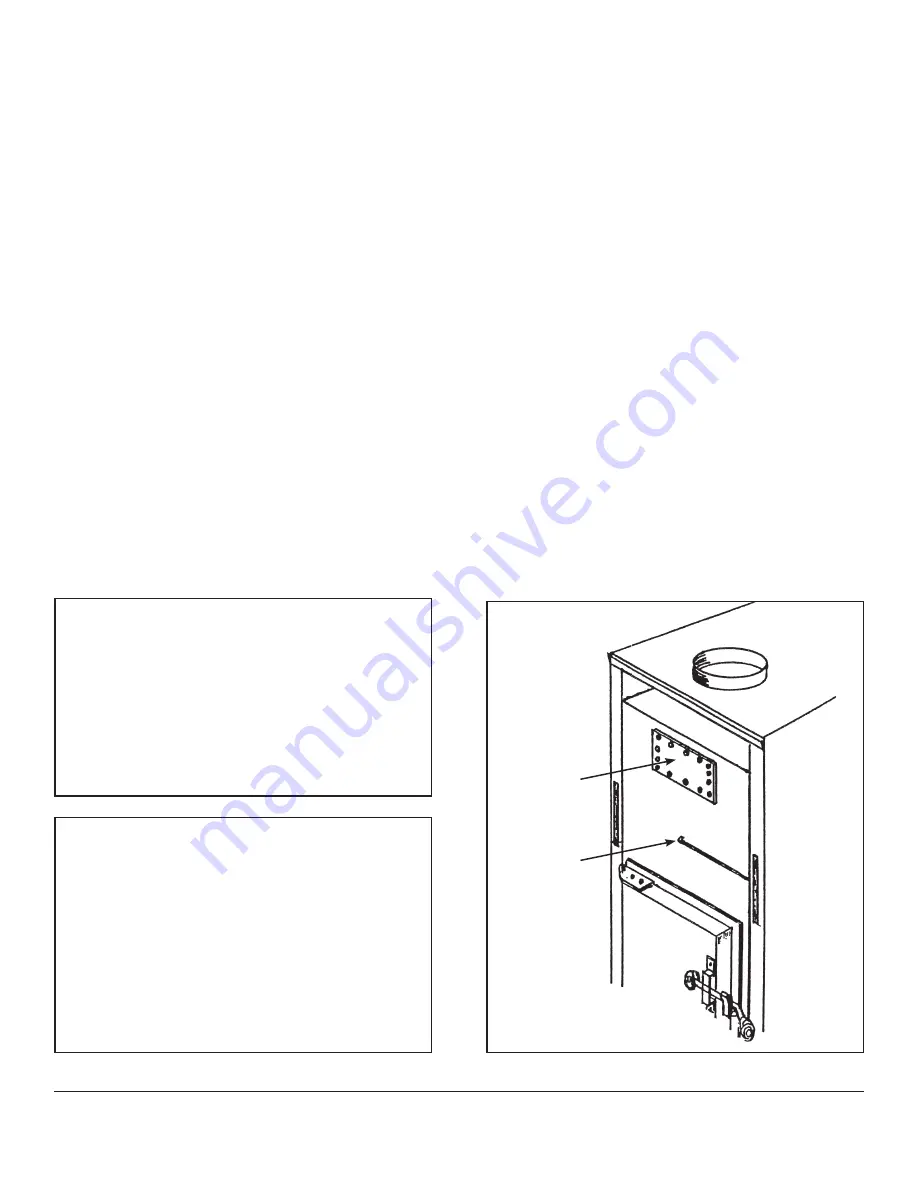

10. Clean out your heat exchanger once or twice

each year to increase the heat transfer efficiency.

See Figure 26.

BOX 422 • TOWER, MN 55790 • USA • Tel (218) 753-2330 • www.lamppakuuma.com

10

IMPortant

runaWay FIre anD CHIMney FIre

CLoSe tHe DraFt IMMeDIateLy.

FueL LoaDInG anD aSH reMoVaL DoorS

are SHut.

CaLL FIre DePartMent.

CautIon

you MuSt CHeCk your CHIMney FLue

PIPe ConneCtor FreQuentLy WHen

FIrSt StartInG to Burn WooD to

DeterMIne tHe aMount oF CHIMney

MaIntenanCe (CLeanInG) tHat WILL

Be reQuIreD. tHIS, oF CourSe, IS aLSo

DePenDent on WooD tyPe, MoISture,

anD, In GeneraL, HoW tHe FurnaCe IS

uSeD.

Figure 26

CLeanout

CoVer

tHerMo

CouPLe