18

3.

Fit the spindle nut and collet assembly onto the spindle thread

by hand.

4.

Press the bit into the collet but note that the flute of the router

bit must not be inside the collet and should be a minimum of

1/16 “ outside the collet.

Hold the router spindle with the supplied

wrench and tighten the collet with a second wrench. Do not over-

tighten.

Note.

Use this process for all other router bits that you need to fit

but you will have to change the collet if the shank of the router bit

is a different size.

Types of router bits

There are five basic types of router bits: straight, up shear, down

shear, combination (also called compression), and form tools

(round over, ogee, etc.).

1.

Straight Router Bits

These are the standard router bits that are commonly used with

handheld routers and are usually available at home centers.

2.

Up Shear Router Bits

These bits have flutes that are spiraled upward (a standard twist

drill is an example of this type of bit). This bit design removes the

chips from the kerf but has a tendency to chip the top surface,

especially veneers or melamine surfaces.

ball nose router bits are a variation of the up shear bit design but have a radiuses end. These

bits are typically used for 3D surfacing applications.

3.

Down Shear Router Bits.

These bits are similar to the up shear but with an opposite spiral that actually tends to pack

the chips into the kerf. These bits prevent chipping the material surface, especially with

veneers or melamine surfaces.

4.

Combination (Compression) Router Bits

These bits combine the advantages of both up shear and down shear designs. The top

section of the tool is down shear to prevent chipping the top surface of the material and the

lower part of the bit is up shear to prevent chipping the bottom surface of the material.

Combination Router Bits are the preferred configuration for machining veneered plywood as

well as melamine surfaced product. A variation of the bit is called the “Mortising

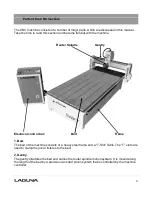

Tightening the spindle

nut

Router bits

Summary of Contents for MCNC Swift 60 X 120-0233

Page 2: ......

Page 11: ...11 Spare drive belts Dust hood Wrenches Table clamps qty 8 Coolant container...

Page 30: ...30 Control cabinet Spindle inverter 24 volt power supply Control cabinet...

Page 32: ...32 Motor drivers 80 Volt power supplies Terminal strip Main power disconnect...

Page 35: ...35 1 Machine not level on the floor Re level the machine ensuring that it has no movement...