LAARS Heating Systems

Page 120

Burner Ignition Sequence

Here is the start-up sequence following a Lead Lag

(LL) Central Heating request:

1. The thermostat used for the LL Central Heat

function calls for heat. On a system set up for

Lead/Lag operation, this will be the System

sensor. (The setpoint or modulation can

also be controlled by an external 4 – 20 mA

control.)

2. The Boiler pump and System pump are

energized. The water temperature in the

System loop drops until it reaches the LL

Central Heat Setpoint minus the LL Central

Heat On Hysteresis value.

3. The controller prepares to start the burner.

The controller does a system check, flap valve

check, and safety chain test. The blower fan is

switched on.

4. The air pressure switch is closed, and the

purge rate proving fan rpm is reached. The

Pre-Purge time starts.

5. When the Purge time is complete, the purge

fan rpm is changed to the Lightoff Rate.

6. When the fan rpm reaches the light-off rpm,

the Pre-Ignition time begins.

7. During the Pre-ignition time, the controller

energizes the igniter and checks for flame.

8. After Pre-ignition, the control enters the

ignition sequence and the gas valve is

energized. The flame signal is compared with

a preset flame threshold value. If the flame

signal is higher than the flame threshold, the

gas valve remains on and the burner is allowed

to continue to the Run phase. If the flame

signal is below the threshold, the controller

returns to the Pre-Purge phase and starts the

ignition process again.

9. The igniter is turned off at the end of the

ignition period.

10. During the Run period, the speed of the

burner fan and the firing rate of the burner(s)

is modulated in response to changes in

demand. (See the next section – “Modulation

Sequence.”)

11. The demand ends when System sensor

temperature equals the Lead/Lag Central Heat

Setpoint plus the Lead/Lag Central Heat Off

Hysteresis value (approx. +10°F).

12. At the end of the Lead/Lag Central Heat

request, the burner is switched off. The fan

stays on until Post Purge is complete.

13. Any new Lead/Lag Central Heat request is

blocked for the Anti Short Cycle time.

14. The Boiler pump and System pump remain on

during their pump overrun times.

15. At the end of the pump overrun times, the

Boiler and System pumps are turned off.

lead/lag modulation Sequence

For a detailed explanation, see Section 9.

Domestic Hot Water Priority

The start-up sequence for a Domestic Hot Water

request, on a system with Domestic Hot Water

priority, is essentially the same as the process we

have just described. The Domestic Hot Water loop

can be considered as just another heating loop on the

system, except the controller can be set to give this

loop priority. The input is supplied by an aquastat,

rather than a thermostat. Circulation in the Domestic

Hot Water loop is provided by a separate pump.

When a Domestic Hot Water demand appears at the

same time as a call for heat by Central Heating, the

priority feature forces the system to switch to the

Domestic Hot Water demand for the priority time.

The Domestic Hot Water priority demand forces the

controller to operate using the DHW setpoint.

For a detailed explanation, see the material on

Domestic Hot Water in Section 9.

Safety Shutdown functions

Each controller has extensive self-checking and

safety features. The controller will shut down the

burner and lock it out under any of the following

conditions:

During the Synchronization Period:

•

Locks out if the Lead/Lag Master cannot

locate any of the boilers, or cannot download

information from any of the controllers.

•

Locks out if the Lead/Lag Master cannot

locate any of the flap valves, or cannot

determine the status of a valve (Open or

Closed).

•

Locks out if a safety-related parameter has

been changed, but the change has not been

verified and the controller has not been reset

using the button on the front of the control.

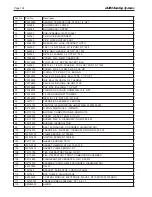

Summary of Contents for NTV1000

Page 2: ......

Page 35: ...NeoTherm Boilers and Water Heaters Page 31 Fig 20 Ladder Diagram...

Page 36: ...LAARS Heating Systems Page 32 Fig 21 Wiring Diagram...

Page 37: ...NeoTherm Boilers and Water Heaters Page 33...

Page 51: ...NeoTherm Boilers and Water Heaters Page 47 Fig 52 Connection Terminals...

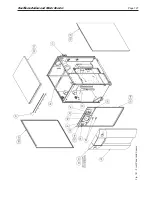

Page 130: ...LAARS Heating Systems Page 126 Fig 140 Machine Frame and Rear Panel 13 3 PARTS ILLUSTRATIONS...

Page 131: ...NeoTherm Boilers and Water Heaters Page 127 Fig 141 Front Panel and Covers...

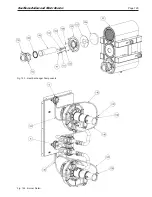

Page 132: ...LAARS Heating Systems Page 128 Fig 142 Burners and Combustion Chambers...

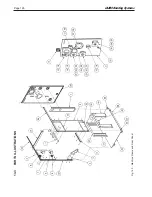

Page 134: ...LAARS Heating Systems Page 130 Fig 145 Electronic Components...

Page 135: ...NeoTherm Boilers and Water Heaters Page 131 Fig 146 Condensate Trap Fig 147 Control Bezel...

Page 136: ...LAARS Heating Systems Page 132 Fig 148 Flow Switch...

Page 137: ...NeoTherm Boilers and Water Heaters Page 133 This page intentionally left blank...