BCU 560, BCU 565 · Edition 02.16

14

Application > Examples of application

1 .1 .8 Modulating burner control

For processes that do not require heavy

circulation in the furnace, e.g. aluminium

smelting furnaces.

This system is suitable for processes in

which infiltrated air may flow into the

furnace through switched off burners.

The capacity can be adjusted continu-

ously by activating the control element

(analogue or 3-point step signal). The

pneumatic ratio control system controls

the gas pressure proportionally to the air

pressure and thus maintains a constant

air/gas ratio. At the same time, it acts

as a low air pressure protection device.

One burner control unit per burner is

required for ignition and monitoring.

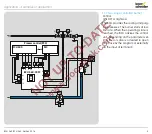

The centrally checked safety functions

such as pre-purge, setting the valve

to ignition position via a butterfly valve

control system, tightness test, flow detec-

tor and pressure switch check (gas

min.

,

gas

max.

, air

min.

) are provided by the

FCU 500.

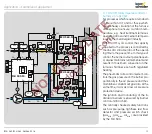

FCU 500..F1

µC

P

DG

DG

DG

VAS

VAS

VCG

VCG

DG

min

DG

max

49

15

13

14

50

53

45

47 48

58

p

u

/2

M

PZL

PZH

PZ

PZL

PDZ

TE

BCU 560..F0

M

M

TC

90°

➔

0°

0°

➔

90°

54

55

VAS

DG

DG

>750°

ϑ

1

2

3

DL

min

DL

Purge

66

BCU 560..F0

66

16

57

STM