Installation and operating instructions

IFC 020

2/3

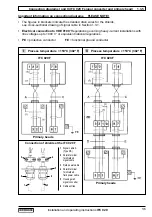

2.4 Input / output connection diagrams

Terminal identification

IFC 020

E

separated, 19” plug-in unit, connection cap

X2

IFC 020

F

separated, field housing

IFC 020

K

compact

For connection and operation of the HART® interface,

see Section 6.1. Load at HART® operation ranges between min.

250

Ω

and max. 500

Ω

.

E: X2

F

K

I

Current output

C

Control input (

IFC 020 E

only)

P

Pulse output

S

Status output

RS 485

Interface

1

2

I

= 0/4 - 20 mA

U

ext

15...20 V DC 20...32 VDC

R

i

0...500

Ω

250...750

Ω

U

ext

≤

15 V DC

I

= 0/4 - 20 mA

R

i

≤

500

Ω

Current output

I

active

Current output

I

passive

Active mode

The current output supplies the power for

operation of the outputs and inputs.

Passive mode

External power source required for operation of

the outputs and inputs.

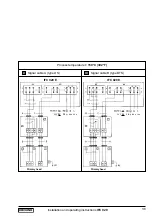

3

4

Pulse output P

passive

for electronic (EC) or

electromechanical (EMC) totalizers

U

ext

≤

30 V DC/

≤

24 V AC

I

max

≤

150 mA

(incl. status output S)

U

int

≤

15 V DC from current output

Operation

with

current output:

I

max

≤

3 mA

Operation

without

current output:

I

max

≤

23 mA

R

≤

15 V

I

max

Pulse output P

active

(and current output I

active

)

for electronic (EC) totalizers

with

and

without

current output I

Totalizer

- electronic (EC)

- electromechanical (EMC)

Milliammeter

0 or 4-20mA and others

Key, N/O contact

External voltage source (U

ext

),

DC or AC voltage,

connection polarity arbitrary

DC voltage,

external power source (U

ext

),

note connection polarity

U

ext

U

ext

I

max

+