.

ATTACHMENTS, OPTIONS

HANDLING AUTO-GREASING SYSTEM

HANDLING AUTO-GREASING SYSTEM

This system uses a timer control to automatically carry out greasing for all parts of the machine. As a result, the

greasing operation can be carried out easily.

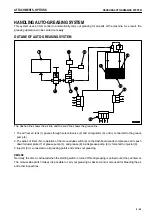

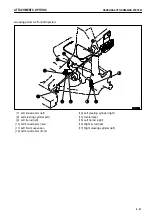

OUTLINE OF AUTO-GREASING SYSTEM

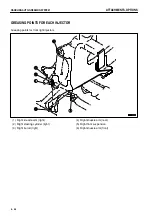

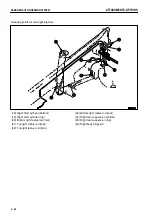

The dashed line shows the air line and the solid line shows the grease line.

1.The air from air tank (1) passes through solenoid valve (2) and air regulator (3), and is connected to the grease

pump (4).

2.The action of timer (5) or operation of the manual lube switch (6) on the dashboard sends compressed air to push

down follower plate (7) of grease pump (4), and grease (8) inside grease pump (4) is force fed to injector (9).

3.Injector (9) is connected to all greasing points and carries out greasing.

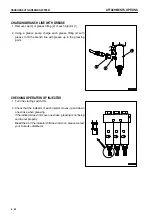

REMARK

Normally, the timer is actuated when the starting switch is turned ON and greasing is carried out at the set interval.

The manual lube switch makes it is possible to carry out greasing as desired, and is also used for bleeding the air

and other inspections.

6 - 45

Summary of Contents for HD785-5

Page 2: ... 1 1 ...

Page 4: ... FOREWORD FOREWORD 1 3 ...

Page 5: ... FOREWORD FOREWORD 1 4 ...

Page 15: ... 2 1 ...

Page 19: ... SAFETY SAFETY LABELS POSITION FOR ATTACHING SAFETY LABELS 2 5 ...

Page 47: ... 3 1 ...

Page 132: ... OPERATION OPERATION Brake performance Downhill distace Continuous Tire size 27 00R49 3 86 ...

Page 166: ... 4 1 ...

Page 237: ... 5 1 ...

Page 239: ... SPECIFICATIONS SPECIFICATIONS 5 3 ...

Page 240: ... 6 1 ...

Page 299: ... 7 1 ...