.

MAINTENANCE

SERVICE PROCEDURE

EVERY 4000 HOURS SERVICE

Carry out the EVERY 100 HOURS MAINTENANCE, EVERY 250 HOURS MAINTENANCE, EVERY 500 HOURS

MAINTENANCE, EVERY 1000 HOURS MAINTENANCE, and EVERY 2000 HOURS MAINTENANCE at the same

time.

CHECK WATER PUMP

Check for play in the pulley, leakage of grease or water, or clogging of the drain hole. If any problem is found, contact

your Komatsu distributor for disassembly and repair or replacement.

CHECK AIR COMPRESSOR

Ask your Komatsu distributor to carry out this work.

CHECK FAN PULLEY AND TENSION PULLEY

Check for play of the pulley and leakage of grease. If any problem is found, please contact your Komatsu distributor.

CHECK VIBRATION DAMPER

There is the possibility of drop in the level of the damper fluid and runout of the concave surface. So, please contact

your Komatsu distributor to inspect or replace.

CHECK INJECTION PUMP RACK RUBBER BOOT, REPLACE

Check the injection pump rack rubber boot for cracks and oil

leakage. If any abnormality is found, please contact your Komatsu

distributor for replacement.

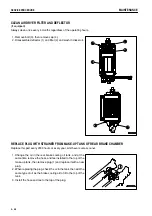

REPLACE INJECTION PUMP SCREEN FILTER

Remove injection pump cap (1), then replace screen filter (2) with

a new part.

The side of the screen filter with the holes is assembled facing the

inside.

Tightening torque of cap (1): 22.1

±

2.45 N

·

m (2.25

±

0.25 kgf

·

m,

16.3

±

1.8lbft)

4 - 69

Summary of Contents for HD785-5

Page 2: ... 1 1 ...

Page 4: ... FOREWORD FOREWORD 1 3 ...

Page 5: ... FOREWORD FOREWORD 1 4 ...

Page 15: ... 2 1 ...

Page 19: ... SAFETY SAFETY LABELS POSITION FOR ATTACHING SAFETY LABELS 2 5 ...

Page 47: ... 3 1 ...

Page 132: ... OPERATION OPERATION Brake performance Downhill distace Continuous Tire size 27 00R49 3 86 ...

Page 166: ... 4 1 ...

Page 237: ... 5 1 ...

Page 239: ... SPECIFICATIONS SPECIFICATIONS 5 3 ...

Page 240: ... 6 1 ...

Page 299: ... 7 1 ...