SECTION 10

RECIRCULATION SYSTEM

Jan 2003

p. 10-1

49836331

Section 10 RECIRCULATION SYSTEM

10 Recirculation

System

The recirculation system keeps the hydraulic oil at operating

temperature while using the minimum amount of cooling water flow. The

system also provides the necessary oil conditioning and filtration to

maintain oil cleanliness. The conditioning of the hydraulic oil includes

cooling it, cleaning it, and together with the hydraulic tank, removing air

bubbles entrained in the oil due to agitation and turbulent flow in the

main pump circuit.

10.1 Components

The cooling and filtration system (recirculation system)

is equipped with

the following:

•

Recirculation pump

(gear-type)–which receives oil from the oil tank

•

Heat exchanger

- cooling water is controlled by the water modulating

valve

Note: Some pumps have no heat exchanger mounted on the reservoir.

Instead, the cutting box/table OEM provides a separate heat exchanger.

Whether mounted on the pump or separate, the gear pump supplies oil

flow to the heat exchanger, then to the oil filter.

•

Oil filter assembly

- includes a gage to show the filter element

condition. It also includes a bypass or relief valve, should the filter

element be allowed to become entirely clogged with

dirt/contaminants.

10.2 Operation

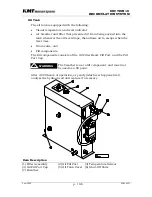

The recirculation pump (1) takes oil from the tank (6) and pumps it to

the oil to water heat exchanger (3), then to the oil filter (5) and back to

the tank.

The pressure gage (4) indicates when the filter element needs

replacement. It should be read when both the water jet pump is running

and the oil temperature is approximately 115

°

F. Failure to properly

service the filter will result in hydraulic oil bypassing the filter element,

and in excessive component wear. The oil fill port must be used when

pumping oil into tank to assure cleanliness. By filling at this point, the

hydraulic oil must pass through the hydraulic filter to get to the

hydraulic tank, guaranteeing that the oil into the tank gets at least one

pass through a good filter.

Summary of Contents for STREAMLINE SL-IV PLUS

Page 44: ...SECTION 6 LOW PRESSURE WATER May 2003 6 4 05148390 Figure 6 2 LP Cutting Water Supply Circuit ...

Page 78: ...SECTION 7 HIGH PRESSURE WATER May 2003 p 7 30 49831951 ...

Page 82: ...SECTION 8 ELECTRICAL SYSTEM Aug 2002 p 8 4 49836323 ...

Page 111: ...SECTION 12 PARTS LISTS July 2003 page 12 5 49836349 ...

Page 113: ...SECTION 12 PARTS LISTS July 2003 page 12 7 49836349 ...

Page 115: ...SECTION 12 PARTS LISTS July 2003 page 12 9 49836349 ...

Page 117: ...SECTION 12 PARTS LISTS July 2003 page 12 11 49836349 ...

Page 119: ...SECTION 12 PARTS LISTS July 2003 page 12 13 49836349 ...

Page 121: ...SECTION 12 PARTS LISTS July 2003 page 12 15 49836349 ...

Page 123: ...SECTION 12 PARTS LISTS July 2003 page 12 17 49836349 ...

Page 125: ...SECTION 12 PARTS LISTS July 2003 page 12 19 49836349 ...

Page 127: ...SECTION 12 PARTS LISTS July 2003 page 12 21 49836349 ...

Page 129: ...SECTION 12 PARTS LISTS July 2003 page 12 23 49836349 ...

Page 131: ...SECTION 12 PARTS LISTS July 2003 page 12 25 49836349 ...

Page 133: ...SECTION 12 PARTS LISTS July 2003 page 12 27 49836349 ...

Page 135: ...SECTION 12 PARTS LISTS July 2003 page 12 29 49836349 ...

Page 137: ...SECTION 12 PARTS LISTS July 2003 page 12 31 49836349 ...

Page 139: ...SECTION 12 PARTS LISTS July 2003 page 12 33 49836349 ...

Page 141: ...SECTION 12 PARTS LISTS July 2003 page 12 35 49836349 ...

Page 143: ...SECTION 12 PARTS LISTS July 2003 page 12 37 49836349 ...

Page 145: ...SECTION 12 PARTS LISTS July 2003 page 12 39 49836349 ...

Page 146: ......

Page 147: ......