E

N

GLISH

6

Keyline S.p.A.

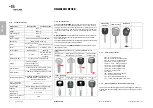

NINJA LASER

Man. cod. B409927FG

Copyright by Keyline - Italy

TRANSPORT AND INSTALLATION

3Transport and installation

3.1.0

Packaging

Packaging includes a cardboard box with the following dimensions:

IMPORTANT!

We recommend you to keep the packaging during the

warranty period.

3.2.0

Transport

The markings on the packing materials indicate how to handle the

machine during transport.

3.2.1

Unloading and handling the machine

The machine can be unloaded manually by 2 or 3 persons, or by using

a handling equipment (for example a lift truck).

Avoid dropping the machine, even a small damage

could impair its correct functioning.

3.3.0

Temporary storing

If the installation of the machine does not occur immediately, store

the machine in a dry and properly ventilated place.

• Apply an appropriate coating.

• Rubber parts must be protected against too low tempera-

tures. Never store them outdoors, not even for short peri-

ods.

If the machine is stored or remains unused for long pe-

riods or if it is started a long time after delivery, gaskets

or retaining rings may undergo hardening thus causing

leaks or seizures.

3.3.1

Characteristics of the place of installation

The key cutting machine must be placed on a smooth level bench

about 90 - 110 cm (35 - 43 Inches) high, suitable for bearing the weight

of the machine and keep it horizontal, thus avoiding vibrations and

stress.

Allow a 30 cm (12 Inches) clearance around and above the key cutting

machine for correct functioning and maintenance.

3.3.2

Temperature and humidity

The tool should be used in rooms with a temperature range of 0 and 40

°C (32.0° - 104.0° F) and a relative humidity lower than 50 - 60%.

3.3.3

Working environment

The machine must be used in a place protected from bad weather

(rain, hail, snow etc.).

If the machine is used in places exposed to corrosion,

maintenance shall be scheduled in such a way as to

prevent extreme wear of the components.

Do not use the machine in explosive or partially explo-

sive atmospheres or in the presence of inflammable

liquids of gases.

3.3.4

Lighting

In the place of installation lighting must be appropriate, in order to al-

low the correct use and maintenance of the machine.

3.4.0

Connections

3.4.1

Grounding

Key cutting machines

NINJA LASER

have been designed in compli-

ance with the safety legislation in force and feature appropriate safe-

ty devices to prevent work accidents. In particular the machine was

built with materials that:

• are self-extinguishing;

• protect against electrocution.

The machine must be grounded through the centralized circuit of the

place of installation.

Warning:

Make sure that the main voltage is compatible with the

machine voltage.

Make sure that the active power outlets are grounded.

Do not touch the machine when your hands and/or feet

are wet or humid.

Avoid any contact with grounded plates.

Dimensions

Machine

Width

440 mm

Height

500 mm

Depth (Length)

540 mm