10

SUPERtrol-I LE Flow Computer

5. UNIT OPERATION

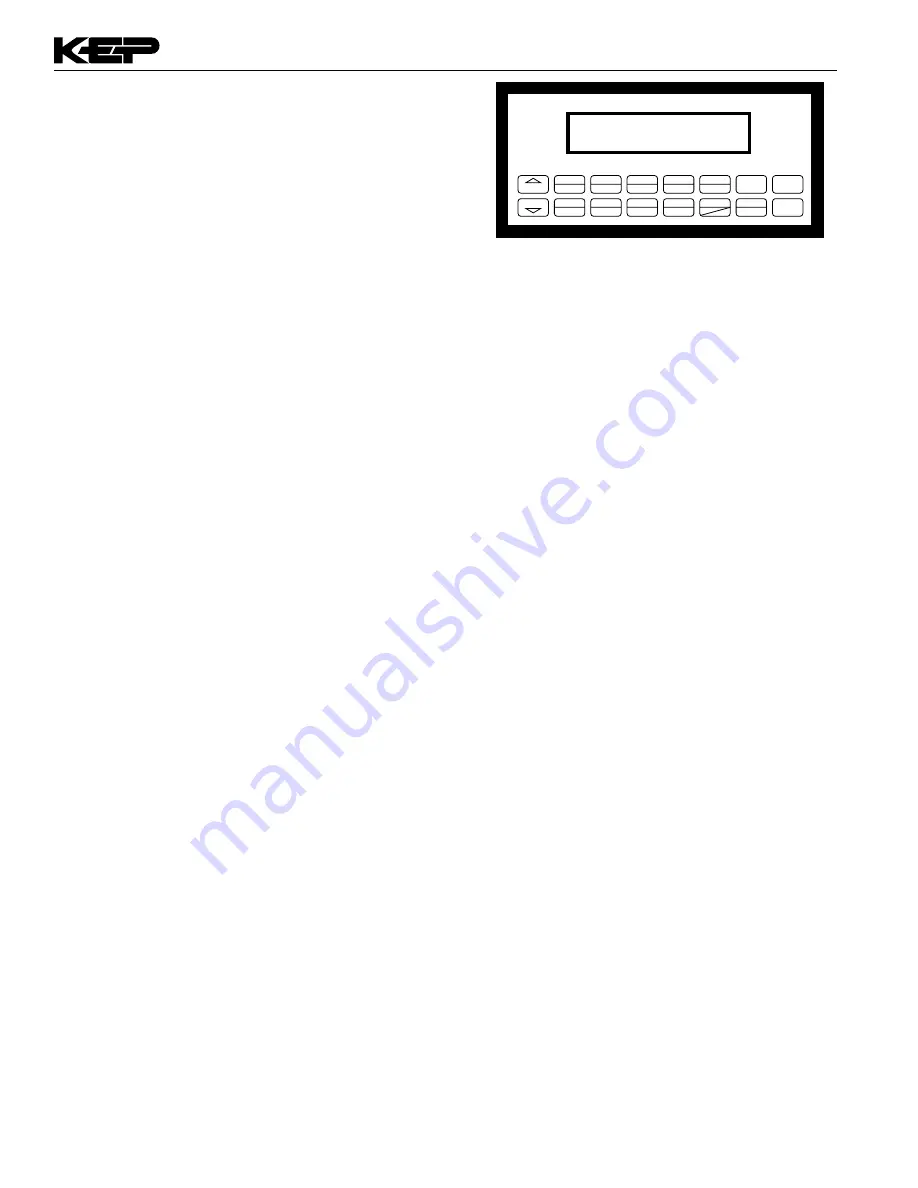

5.1 Front Panel Operation Concept for Run Mode

The ST1LE is fully programmable through the front

panel. Please review the following usage summary

before attempting to use the instrument.

HELP

On-line help is provided to assist the operator in using this product. The help is available during RUN and SETUP

modes simply by pressing the HELP key. The HELP key is used to enter decimals when entering numeric values.

FUNCTION KEYS

In the RUN mode, several keys have a special, direct access feature, to display an item of interest (i.e. RATE,

TOTAL, PRE 1, etc.). Press the key to view your choice. Press the SCROLL key to return to scrolling display.

CLEARING TOTALIZER

To clear the total, you must press the TOTAL Function Key 3 times quickly to select the total. Once the total is

selected, press the CLEAR key to reset the total. The operator will be prompted to enter password if the unit is

locked.

NOTE: In the Batcher Mode, simply press the CLEAR key to reset the total (the batcher must be stopped or finished

batching). It is not necessary to press the TOTAL Function Key first.

CLEARING GRAND TOTAL

To clear the grand total, you must press the GRAND Function Key 3 times quickly to select the grand total. Once

the grand total is selected, press the CLEAR key to reset the grand total. The operator will be prompted to enter

password if the unit is locked.

PRESET KEYS

In the RUN mode, PRE 1, PRE 2, F1 and F2 keys are used to view and/or change the preset setpoints. To view the

Presets, simply press the desired Preset key once. Rapidly press the Preset keys 3 times, then press the Clear key

for direct editing of the preset setpoints.

SCROLL

Rapidly press the Scroll key 3 times to setup a display list.

Press the CLEAR key to remove old scroll list.

Press the function key for the item you wish to add

Use the

∆ ∇

keys to assign the line.

Press the ENTER key to save scroll list.

PRINT

The PRINT key is used to print on demand. When the PRINT key is pressed, a user defined list of data (TOTAL,

RATE, PRE 1, etc.) is sent to the RS232 port. A timed message of "PRINTING" will be displayed to acknowledge the

print request.

SPECIAL BATCHING KEYS

The START and STOP keys are used only when batching to start and stop batches. The CLEAR key will clear the

total without first pressing the TOTAL key (unit must be stopped). All other keys work the same in both Rate/Total

mode and Batch mode. The Start and Stop keys operation are set by the control input settings. The Start options are:

START or RESET/START. The Stop options are: STOP or STOP/RESET.

MENU KEY

The MENU key is used to enter the Setup and Test modes. Press the MENU key to enter the Setup and Test modes.

The user will be prompted to enter a password if the unit is locked. (See section 6 for Setup mode, section 8 for Test

mode). The MENU key is also used as "escape" in Setup and Test Programming. Pressing the MENU key while

programming in the Sub-Menu groups will backup the display to that Sub-Menu group heading. Pressing the MENU

key while viewing the Sub-Menu groups will backup the display to the Top Level Menu.

ACKNOWLEDGING ALARMS

Most alarm messages are self-clearing. Press the ENTER key to acknowledge and clear alarms.

NOTE: Some keys and functions are password protected. Enter the password to gain access. The passwords are

factory set as follows: Operator = 0; Supervisor = 2000

TIME/DATE

The TIME key is reserved for displaying Time and Date. To View the Time or Date, press the TIME key once.

STOP

START

5

0

–

CLEAR

•

MENU

ENTER

HELP

4

PRE 1

3

RATE

2

TOTAL

1

GRAND

6

SCROLL

7

PRE 2

8

9

F4

F1

F2

F3