ANTRIEBSTECHNIK

GB 59

GB

9. Start-Up

Assistance

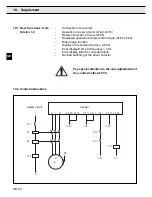

9.2 Adjustment Assistance

for Conventional Lift

Motors

The inverter KEB COMBIVERT F4-F Lift is suited for modern lift/

industrial motors as well as conventional lift motors and thus for

modernization.

In contrast to modern lift motors and industrial motors, conventional

and old lift motors have a ‘soft’ torque-speed-characteristic. This can

be seen in the rated speeds. Typical for modern machines is 1450

rpm (with 4-pole motors) and with conventional motors 1380 rpm or

880 rpm (6-pole machines).

Often the specifications on the name plate are inadequate or non-

existant. In this case the motor data must be adjusted on-site for the

system.

If the lift does not reach the rated speed during ‘no-load-downward-

drive’ (display LF.90), do the following:

1.) Decrease field weakening speed (LF.16) to approx. 2/3 of the

synchronous speed (approx. 1000 rpm with 4-pole motors;

approx. 680 rpm with 6-pole motors).

2.) Set cos phi (LF.15) to 0,9

3.) Decrease rated motor speed LF.11 in steps of 20 until the rated

speed is reached during a downward drive.

When the power consumption of the motor is too high (display in

ru.02 or LF.87) it helps to increase LF.11 in steps of 10. At the same

time control whether the ‘no-load downward-drive’ can be driven

with rated speed.

If possible remove hand wheels with big inertia. If this is not possible,

then the starting jerk (LF.50) and acceleration (LF.51) should be low

(both values approx. 0.4), so that the motor is not overstressed.

Summary of Contents for COMBIVERT F4-F

Page 65: ...ANTRIEBSTECHNIK...