MAINTENANCE

7-52

Check Pilot Circuit Accumulator Function, Gas

Leakage, Looseness, and Damage

--- every 2000 hours

WARNING: Allow only qualified personnel to handle

the accumulator.

y

High-pressure nitrogen gas is enclosed in the

accumulator. (N

2

is inert.)

y

Never strike the accumulator. Keep the accumulator

away from heat sources.

y

Do not weld the accumulator housing.

y

Be sure to release oil pressure before starting to

work on pilot circuits.

1. Park the machine following the same procedures as

described on page 7-7 for preparation of inspection/

maintenance work.

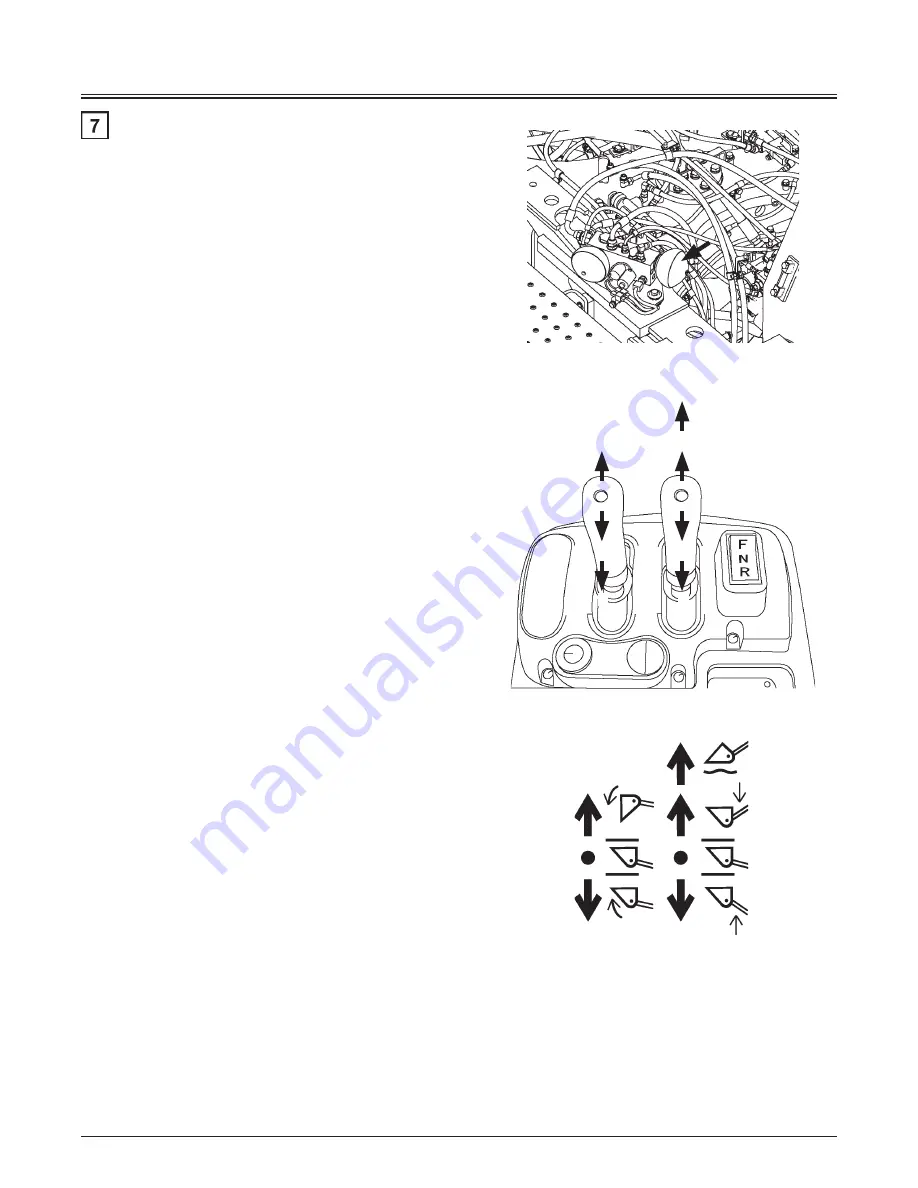

2. Raise the lift arm at the maximum height, and then set

the lift arm control lever in the Neutral (N) position.

3. Turn the key switch OFF to stop the engine.

4. Turn the key switch to ON position. (Do not start the

engine.)

5. Confirm the safety around the machine.

6. Place the lift arm control lever to FLOAT position (C) and

lower the bucket 1 m (40 in) off the ground within 2

minutes after stopping the engine.

7. Place the lift arm control lever to the LOWER position (B)

and lower the bucket the rest of the way to the ground.

8. Ensure the lift arm does not stop halfway. If the lift

arm stops halfway, the accumulator function may be

deteriorated. Consult your nearest authorized dealer for

check and repair.

E

N

D

B

N

A

C

D

A

E

B

C

N

N

G

F

MNEC-07-069

M4GB-01-072

MNEC-03-003

Summary of Contents for 70Z7

Page 2: ...93108 00691 April 2015...

Page 5: ......

Page 11: ...MACHINE NUMBERS 2 MEMO...

Page 51: ...SAFETY LABELS S 40 6 10 4 1 3 9 6 5 SS 3461...

Page 171: ...OPERATOR S STATION 1 110 MEMO...

Page 173: ...BREAK IN 2 2 MEMO...

Page 187: ...OPERATING THE ENGINE 3 14 MEMO...

Page 231: ...OPERATING THE MACHINE 5 24 MEMO...

Page 359: ...MAINTENANCE 7 118 MEMO...

Page 363: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 4 MEMO...

Page 367: ...STORAGE 10 4 MEMO...