MAINTENANCE

7-47

1

2

5

4

3

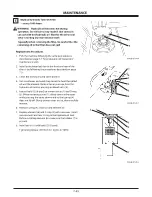

Replace Pilot Oil Filter

--- every 2000 hours

WARNING: Hydraulic oil becomes hot during

operation. Severe burns may result if skin comes in

contact with hot hydraulic oil. Wait for the oil to cool

before starting any maintenance work.

IMPORTANT: Remove trapped hydraulic circuit pressure

by using the loader control levers.

1. Park the machine following the same procedures as

described on page 7-7 for preparation of inspection/

maintenance work.

2. Install articulation lock bar to the front and rear of the

chassis by following the procedures described on page

7-9.

3. Before replacing the filter element, be sure to relieve the

air pressure from the hydraulic oil tank by pressing air

bleed valve (1).

4. Remove the inspection cover for left side rear frame.

5. Rotate the hexagonal section on the bottom of case (2)

counterclockwise using a wrench to remove case (2)

from head cover (3).

6. While turning element (5), remove the element

downward.

7. Replace O-ring (4) with a new one.

8. Seat O-ring (4) in the O-ring groove on head cover (3).

9. Coat the seal surface of new element (5) with hydraulic

oil. While turning element (5), completely install element

(5) into head cover (3) using care not to damage the

element.

2

M4GB-07-044

M4GB-07-050

MNEC-07-019

Summary of Contents for 70Z7

Page 2: ...93108 00691 April 2015...

Page 5: ......

Page 11: ...MACHINE NUMBERS 2 MEMO...

Page 51: ...SAFETY LABELS S 40 6 10 4 1 3 9 6 5 SS 3461...

Page 171: ...OPERATOR S STATION 1 110 MEMO...

Page 173: ...BREAK IN 2 2 MEMO...

Page 187: ...OPERATING THE ENGINE 3 14 MEMO...

Page 231: ...OPERATING THE MACHINE 5 24 MEMO...

Page 359: ...MAINTENANCE 7 118 MEMO...

Page 363: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 4 MEMO...

Page 367: ...STORAGE 10 4 MEMO...