– 3

Quality requirements for water:

ATTENTION

Only clean water may be used as high

pressure medium. Impurities will lead to in-

creased wear and tear or formation of de-

posits in the appliance.

If recycled water is used, the following limit

values must not be exceeded.

Please follow the national rules and

regulations for fluid spray jets of the re-

spective country.

Please follow the national rules and

regulations for accident prevention of

the respective country. Fluid spray jets

must be tested regularly and the results

of these tests must be documented in

writing.

The appliance/accessories must not be

modified.

DANGER

–

Do not use high pressure cleaners

when there has been an oil spill; move

the appliance to another spot and avoid

any sort of spark formation.

–

Do not store, spill or use fuel in the vi-

cinity of open flames or appliances such

as ovens, boilers, water heaters, etc.

that have an ignition flame or can gen-

erate sparks.

–

Keep even mildly inflammable objects

and materials away from the muffler (at

least 2 m).

–

Do not start the engine without the muf-

fler; check, clean and replace, if re-

quired, the muffler at regular intervals.

–

Do not use the engine in forest, bushes

or grassy areas without fitting a spark

receiver at the exhaust

–

Except for setting jobs, do not run the en-

gine when the air filter is removed or there

is no cover over the suction support.

–

Do not make any adjustments to the

regulator springs, regulator bars or oth-

er parts that can bring forth an increase

in the engine speed.

–

Risk of burns! Do not touch hot muf-

flers, cylinders or radiator ribs.

–

Do not put hands or feet close to mov-

ing or rotating parts.

–

Risk of poisoning! The appliance should

not be operated in closed rooms.

–

Do not use unsuitable fuels, as they

may be dangerous.

Safety devices serve for the protection of the

user and must not be put out of operation or

bypassed with respect to their function.

– If the hand spray gun is closed, the

overflow valve opens and the high pres-

sure pump diverts the water back to the

pump suction side. Thus the permissi-

ble working pressure is not exceeded.

– The overflow valve is set by the manu-

facturer and sealed. Setting only by

customer service.

Please do not let mineral oil contaminated

waste water reach soil, water or the sew-

age system. Perform engine cleaning and

bottom cleaning therefore only on speci-

fied places with an oil trap.

pH value

6,5...9,5

electrical conductivity *

Conductivity

fresh water

+1200 μS/cm

settleable solids **

< 0,5 mg/l

total suspended solids *** < 50 mg/l

Hydrocarbons

< 20 mg/l

Chloride

< 300 mg/l

Sulphate

< 240 mg/l

Calcium

< 200 mg/l

Total hardness

< 28 °dH

< 50 °TH

< 500 ppm

(mg CaCO

3

/l)

Iron

< 0,5 mg/l

Manganese

< 0,05 mg/l

Copper

< 2 mg/l

Active chloride

< 0,3 mg/l

free of bad odours

* Maximum total 2000 μS/cm

** Test volume 1 l, settling time 30 min

*** no abrasive substances

Safety instructions

Safety Devices

Overflow valve

19

EN

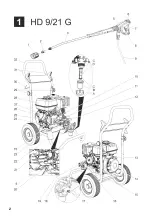

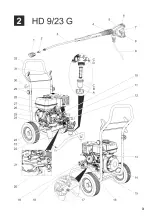

Summary of Contents for HD 9/21 G

Page 1: ...HD 9 21 G HD 9 23 G 001 59672320 10 16 English...

Page 2: ...2...

Page 3: ...3...

Page 4: ...4...

Page 18: ...4 2 158 RU...

Page 19: ...5 80 C 3 EASY Lock EASY Lock EASY Lock EASY Lock MIN 2 1 159 RU...

Page 20: ...6 E10 7 5 3 4 3 4 0 160 RU...

Page 21: ...7 1 K rcher HD 9 21 G HD 9 23 G 161 RU...

Page 22: ...8 K rcher 0 6 1 5 0 1 2 3 0 OFF 162 RU...

Page 23: ...9 1 0 OFF 500 163 RU...

Page 24: ...10 1 0 OFF 3 164 RU...

Page 25: ...11 www kaercher com 2 637 002 0 2 637 007 0 Cage 30190 3 0 1 9 0 30190 09 2 013 165 RU...