– 4

The safety valve opens when the permissi-

ble operating pressure is exceeded (see

Technical Data); water flows outside.

The safety valve is set by the manufacturer

and sealed. Setting only by customer ser-

vice.

The thermostat valve protects the high-

pressure pump from unacceptable heating

during circuit operation when the trigger

gun is closed.

The thermostat valve opens when the per-

missible water temperature of 80°C is ex-

ceeded and lets out the hot water into the

open.

DANGER

Risk of injury! Device, tubes, high pressure

hose and connections must be in faultless

condition. If they are not in a perfect state

then the appliance must not be used.

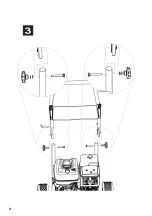

Figure 3, see cover page

Fasten the push handle by means of

the fastening screws.

Note:

The EASY!Lock system joins com-

ponents with a quick-fasten thread solidly

and securely with just one turn.

Insert the high pressure nozzle onto the

spray lance.

Install union nut and hand-tighten it

(EASY!Lock).

Join the spray lance with the trigger gun

and tighten until hand-tight

(EASY!Lock).

Tighten the screw connection of the

spray lance finger tight.

Join the high-pressure hose with trigger

gun and high-pressure connection of

the appliance and tighten until hand-

tight (EASY!Lock).

Check oil level of the high pressure

pump at the oil sight glass.

Do not operate the device if the oil level has

fallen below the middle of the oil sight

glass.

Add oil if required (see technical speci-

fications).

Before using for the first time, cut off the

tip of the lid of the oil tank on the water

pump.

Follow the instructions given in the sec-

tion "Safety Notes"!

Read the operating instructions of the en-

gine manufacturer before start-up and fol-

low the safety instructions carefully.

Check oil level of the engine.

Do not operate the appliance if the oil

level has fallen below "MIN".

If required, top up oil carefully.

Fill the fuel tank with unleaded petrol.

Do not use 2-speed mixture.

E10 fuel may be used.

Safety valve

Thermostat valve

Start up

Installing the pushing handle

Install hand spray gun, spray lance

and nozzle

2.

1.

Check oil level of the high pressure

pump

Motor

20

EN

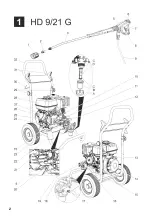

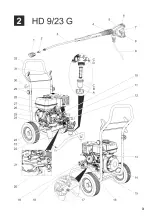

Summary of Contents for HD 9/21 G

Page 1: ...HD 9 21 G HD 9 23 G 001 59672320 10 16 English...

Page 2: ...2...

Page 3: ...3...

Page 4: ...4...

Page 18: ...4 2 158 RU...

Page 19: ...5 80 C 3 EASY Lock EASY Lock EASY Lock EASY Lock MIN 2 1 159 RU...

Page 20: ...6 E10 7 5 3 4 3 4 0 160 RU...

Page 21: ...7 1 K rcher HD 9 21 G HD 9 23 G 161 RU...

Page 22: ...8 K rcher 0 6 1 5 0 1 2 3 0 OFF 162 RU...

Page 23: ...9 1 0 OFF 500 163 RU...

Page 24: ...10 1 0 OFF 3 164 RU...

Page 25: ...11 www kaercher com 2 637 002 0 2 637 007 0 Cage 30190 3 0 1 9 0 30190 09 2 013 165 RU...