– 2

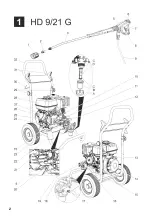

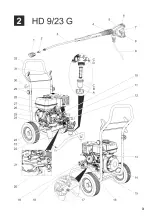

14 Device for manual start

15 Oil drain screw (engine)

16 Detergent suction hose with filter

17 Nozzle holder

for storing a nozzle

18 Water filter

19 Water connection

20 Oil drain screw pump

21 Oil sight glass

22 Storage for spray pipe

23 High pressure pump

24 Oil dip (engine)

25 Motor

26 Engine switch

27 High-pressure connection EASY!Lock

28 Fuel tank

29 Star knob push handle

30 Trigger gun storage clip

31 Hose switch

32 Push handle

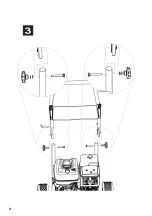

A Union joint

B Filter pot

C O ring

D Filter inlay

– The operating elements for the cleaning

process are yellow.

– The controls for the maintenance and

service are light gray.

High-pressure jets can be dan-

gerous if improperly used. The

jet may not be directed at persons, animals,

live electrical equipment or at the appliance

itself.

According to applicable regula-

tions, the appliance must never be

used on the drinking water net

without a system separator. A suit-

able system separator by KÄRCHER or al-

ternatively a system separator according to

EN 12729 type BA must be used.

Water that was flowing through a system

separator is considered non-drinkable.

High pressure cleaner to clean: Machines,

Vehicles, Structures, Tools, Facades, Ter-

races, Gardening tools, etc.

– Cleaning using low pressure jet and de-

tergent (for e.g. for cleaning machines,

cars, buildings, tools),

– For cleaning using high pressure jet

without detergent (for e.g. for cleaning

facades, terraces, garden appliances).

– For stubborn dirt, we recommend the

use of the dirt blaster as a special ac-

cessory.

DANGER

Risk of injury! Follow the respective safety

regulations when operating at gas stations

or other dangerous areas.

Colour coding

Symbols on the machine

Risk of burns! Beware of hot

components.

Risk of poisoning! Do not

breathe in the exhaust fumes.

Petrol is highly prone to

fire hazards and is ex-

plosive.

Before tanking up,

switch off the motor and

allow it to cool down.

The motor exhaust gas

contains poisonous car-

bon monoxide.

Do not run the engine in

closed areas.

Do not fill up when the

motor is running.

Do not smoke during

fueling.

Do not fill up directly

from the can; use a fun-

nel or suitable container.

Proper use

18

EN

Summary of Contents for HD 9/21 G

Page 1: ...HD 9 21 G HD 9 23 G 001 59672320 10 16 English...

Page 2: ...2...

Page 3: ...3...

Page 4: ...4...

Page 18: ...4 2 158 RU...

Page 19: ...5 80 C 3 EASY Lock EASY Lock EASY Lock EASY Lock MIN 2 1 159 RU...

Page 20: ...6 E10 7 5 3 4 3 4 0 160 RU...

Page 21: ...7 1 K rcher HD 9 21 G HD 9 23 G 161 RU...

Page 22: ...8 K rcher 0 6 1 5 0 1 2 3 0 OFF 162 RU...

Page 23: ...9 1 0 OFF 500 163 RU...

Page 24: ...10 1 0 OFF 3 164 RU...

Page 25: ...11 www kaercher com 2 637 002 0 2 637 007 0 Cage 30190 3 0 1 9 0 30190 09 2 013 165 RU...