– 6

Open the water supply.

Start the motor with the trigger gun

open according to the operating instruc-

tions of the motor manufacturer.

Note:

The spray lance can be removed to facili-

tate the start-up process.

Allow motor to warm up for 1 minute.

Release the trigger gun. To do so, push

the safety catch towards the back.

Open the hand spray gun.

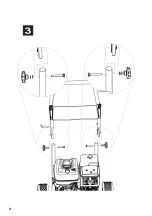

Set the working pressure and quantity

by turning the pressure/ quantity regula-

tion mechanism at the pump unit.

Set (+/-) the working pressure and

quantity by turning the pressure/ quan-

tity regulation mechanism at the hand

spray gun.

DANGER

When adjusting the pressure/quantity regu-

lation, make sure that the screw connection

of the spray lance does not become loose.

DANGER

Switch the appliance off prior to replacing

nozzel and activate hand spray gun until

device is pressureless.

Secure the trigger gun. To do so, push

the safety catch towards the front.

Unscrew nozzle screws and remove the

nozzle.

Put on a new nozzle.

Screw on the nozzle screws and tighten

them by hand.

몇

WARNING

Unsuitable detergents can cause damage

to the appliance and to the object to be

cleaned. Use only those detergents that

have been approved by Kärcher. Observe

the dosage and other instructions provided

with these detergents. For considerate

treatment of the environment use detergent

economically.

Follow the safety instructions for using de-

tergents.

Kärcher detergents ensure smooth func-

tioning. Please consult us or ask for our cat-

alogue or our detergent information sheets.

Suspend end of suction hose in a con-

tainer filled with detergent.

Replace the high-pressure nozzle with

the low-pressure nozzle.

Set dosing value for detergent to the

desired concentration.

Set dosing valve for detergent to the de-

sired concentration (0%–6%).

– Loosen the dirt:

Spray detergent economically and let it

work for 1...5 minutes but do not let it

dry up.

– Remove the dirt:

Spray off loosened dirt with the high

pressure jet.

Set dosing value for detergent to "0".

Open the trigger gun and rinse the de-

vice with the motor running for at least 1

minute.

Release the lever on the trigger gun.

Note:

When the lever of the hand spray

gun is released, the engine continues to run

at zero speed.

In case of extended interruptions (sev-

eral minutes), switch off the engine.

Activate trigger gun until device is pres-

sure-less.

Secure the hand spray gun using the

safety catch so that it doesn't open ac-

cidentally.

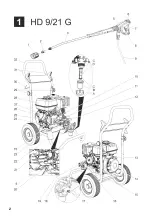

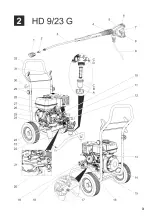

Starting the machine

Set working pressure and flow rate

HD 9/21 G

HD 9/23 G

Replace the nozzle

Operation with detergent

Recommended cleaning method

After operation with detergent

Interrupting operation

22

EN

Summary of Contents for HD 9/21 G

Page 1: ...HD 9 21 G HD 9 23 G 001 59672320 10 16 English...

Page 2: ...2...

Page 3: ...3...

Page 4: ...4...

Page 18: ...4 2 158 RU...

Page 19: ...5 80 C 3 EASY Lock EASY Lock EASY Lock EASY Lock MIN 2 1 159 RU...

Page 20: ...6 E10 7 5 3 4 3 4 0 160 RU...

Page 21: ...7 1 K rcher HD 9 21 G HD 9 23 G 161 RU...

Page 22: ...8 K rcher 0 6 1 5 0 1 2 3 0 OFF 162 RU...

Page 23: ...9 1 0 OFF 500 163 RU...

Page 24: ...10 1 0 OFF 3 164 RU...

Page 25: ...11 www kaercher com 2 637 002 0 2 637 007 0 Cage 30190 3 0 1 9 0 30190 09 2 013 165 RU...