– 8

Check the high pressure hose for dam-

ages (risk of bursting). Please arrange

for the immediate exchange of a dam-

aged high-pressure hose.

Check oil level.

Please contact Customer Service immedi-

ately if the oil is milky (water in oil).

Clean water filter.

Clean filter at the detergent suck hose.

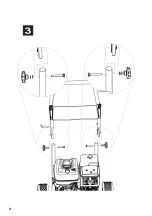

Check the fastening elements between

the motor and frame for cracks; have

cracked fastening elements replaced by

Customer Service.

Have the maintenance of the device

performed by the customer service.

Change the oil in the high pressure pump.

Shut off water supply.

Unscrew the covering nut.

Remove the filter cup towards the bottom.

Clean filter inlay and filter cup.

Check the O-rings for proper seating.

Insert the filter inlay into the filter cup.

Replace the filter cup.

Screw on and tighten the union nut.

Oil change:

Ready a catch bin for appr. 1 Liter oil.

Turn out the oil drain screw.

Drain the oil in a collection basin.

Screw in the oil drain screw.

Fill in new oil up to the middle of the oil

sight glass.

Add oil slowly so that air bubbles can es-

cape.

For oil type refer to technical specifica-

tions.

DANGER

Risk of injury if the machine is left running

in an unattended state.

Before working on the device, turn the start-

er to "0/OFF" and remove the spark plug

connector.

Risk of burns! Do not touch hot mufflers,

cylinders or radiator ribs.

Follow operating instructions of the engine

manufacturer!

– Operating speed of the engine is too

low

Check operating speed of the engine

(refer to technical data).

– Low-pressure nozzle is installed.

Install the high pressure nozzle.

– Nozzle is blocked/ washed out

Clean/ replace nozzle.

– Water filter contaminated

Clean water filter.

– Air within the system

Deaerate the appliance (see "Start-up")

– Amount of water supply is too low.

Check water supply level (refer to tech-

nical data).

– Pipe inlets to pump are leaky or blocked

Check all inlet pipes to the pump.

– Pump leaky

Note:

3 drops/minute are allowed.

With stronger leak, have device

checked by customer service.

Maintenance intervals

Daily

Weekly

Monthly

After 500 operating hours, at least

annually

Maintenance Works

Clean water filter.

Oil change in high pressure pump

Dispose of old oil ecologically or turn it in at

a collection point.

Troubleshooting

Motor does not run

Device is not building up pressure

Device leaks, water drips from the

bottom of the device

24

EN

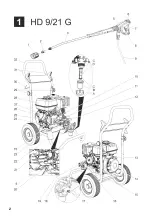

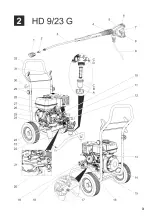

Summary of Contents for HD 9/21 G

Page 1: ...HD 9 21 G HD 9 23 G 001 59672320 10 16 English...

Page 2: ...2...

Page 3: ...3...

Page 4: ...4...

Page 18: ...4 2 158 RU...

Page 19: ...5 80 C 3 EASY Lock EASY Lock EASY Lock EASY Lock MIN 2 1 159 RU...

Page 20: ...6 E10 7 5 3 4 3 4 0 160 RU...

Page 21: ...7 1 K rcher HD 9 21 G HD 9 23 G 161 RU...

Page 22: ...8 K rcher 0 6 1 5 0 1 2 3 0 OFF 162 RU...

Page 23: ...9 1 0 OFF 500 163 RU...

Page 24: ...10 1 0 OFF 3 164 RU...

Page 25: ...11 www kaercher com 2 637 002 0 2 637 007 0 Cage 30190 3 0 1 9 0 30190 09 2 013 165 RU...