– 5

DANGER

Risk of fire and explosion!

–

Never use the appliance in closed

rooms; do not tank up when the engine

is hot or running.

–

Do not smoke during fueling.

–

Never fill up in the vicinity of open

flames or sparks.

–

Do not spill any fuel – use a funnel.

–

Wipe up spilled fuel.

–

After refuelling, properly close the can

and tank.

Fill the fuel tank with unleaded petrol.

Do not use 2-speed mixture.

For connection values refer to technical

specifications.

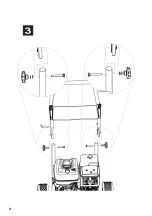

Connect the supply hose (minimum

length 7.5 m, minimum diameter 3/4“) to

the water connection point of the ma-

chine and at the water supply point (for

e.g. a tap).

Open the water supply.

Note:

The supply hose is not included.

DANGER

Never suck water from a drinking water

container.

Never suck in liquids which contain sol-

vents like lacquer thinner, petrol or oil. The

spray mist of solvents is highly inflamma-

ble, explosive and poisonous.

Connect suction hose (minimum diame-

ter 3/4“) with filter (accessory) to the

water connection point.

Set dosing value for detergent to "0".

Remove air from appliance before oper-

ation.

Unscrew nozzle screws and remove the

nozzle.

Start the engine according to the oper-

ating instructions of the engine manu-

facturer.

Press the lever on the trigger gun many

times.

Switch on the appliance and let it run

until the water exiting from the spray

pipe is bubble-free.

Switch off the appliance and fit the noz-

zle again.

DANGER

Risk of explosion!

Do not spray flammable liquids.

DANGER

Risk of injury! Never use the appliance

without the spray lance attached. Check

and ensure proper fitting of the spray lance

prior to each use. The screw connection of

the spray lance must be finger-tight.

Risk of injury! Hold the hand spray gun and

the spray pipe firmly with both hands.

Risk of injury! The trigger and safety lever

may not be locked during the operation.

Risk of injury! Contact Customer Service if

the safety lever is damaged.

Risk of injury from high-pressure water jet.

Slide the safety catch on the trigger gun for-

ward before performing any work with the

appliance.

DANGER

–

The device generates a high noise lev-

el. Risk of hearing impairment. Always

use proper hearing protection while

working with the device.

–

Never direct the water jet on to persons,

animals, the appliance itself or electrical

components.

–

The operator must wear proper safety

gear to be protected against the water

sprays.

–

Pay attention to ensure that all screws

of all connecting hoses are tightened

properly.

To open the trigger gun: Actuate the

safety lever and trigger.

To close the hand spray gun: Release

the safety lever and trigger.

Refuel

Water connection

Suck in water from vessel

Dearating the appliance

Operation

Opening/closing the trigger gun

21

EN

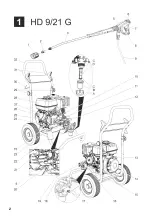

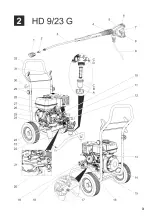

Summary of Contents for HD 9/21 G

Page 1: ...HD 9 21 G HD 9 23 G 001 59672320 10 16 English...

Page 2: ...2...

Page 3: ...3...

Page 4: ...4...

Page 18: ...4 2 158 RU...

Page 19: ...5 80 C 3 EASY Lock EASY Lock EASY Lock EASY Lock MIN 2 1 159 RU...

Page 20: ...6 E10 7 5 3 4 3 4 0 160 RU...

Page 21: ...7 1 K rcher HD 9 21 G HD 9 23 G 161 RU...

Page 22: ...8 K rcher 0 6 1 5 0 1 2 3 0 OFF 162 RU...

Page 23: ...9 1 0 OFF 500 163 RU...

Page 24: ...10 1 0 OFF 3 164 RU...

Page 25: ...11 www kaercher com 2 637 002 0 2 637 007 0 Cage 30190 3 0 1 9 0 30190 09 2 013 165 RU...