➤ Take note of the controller's service messages and carry out tasks punctually, taking ambient

and operating conditions into account:

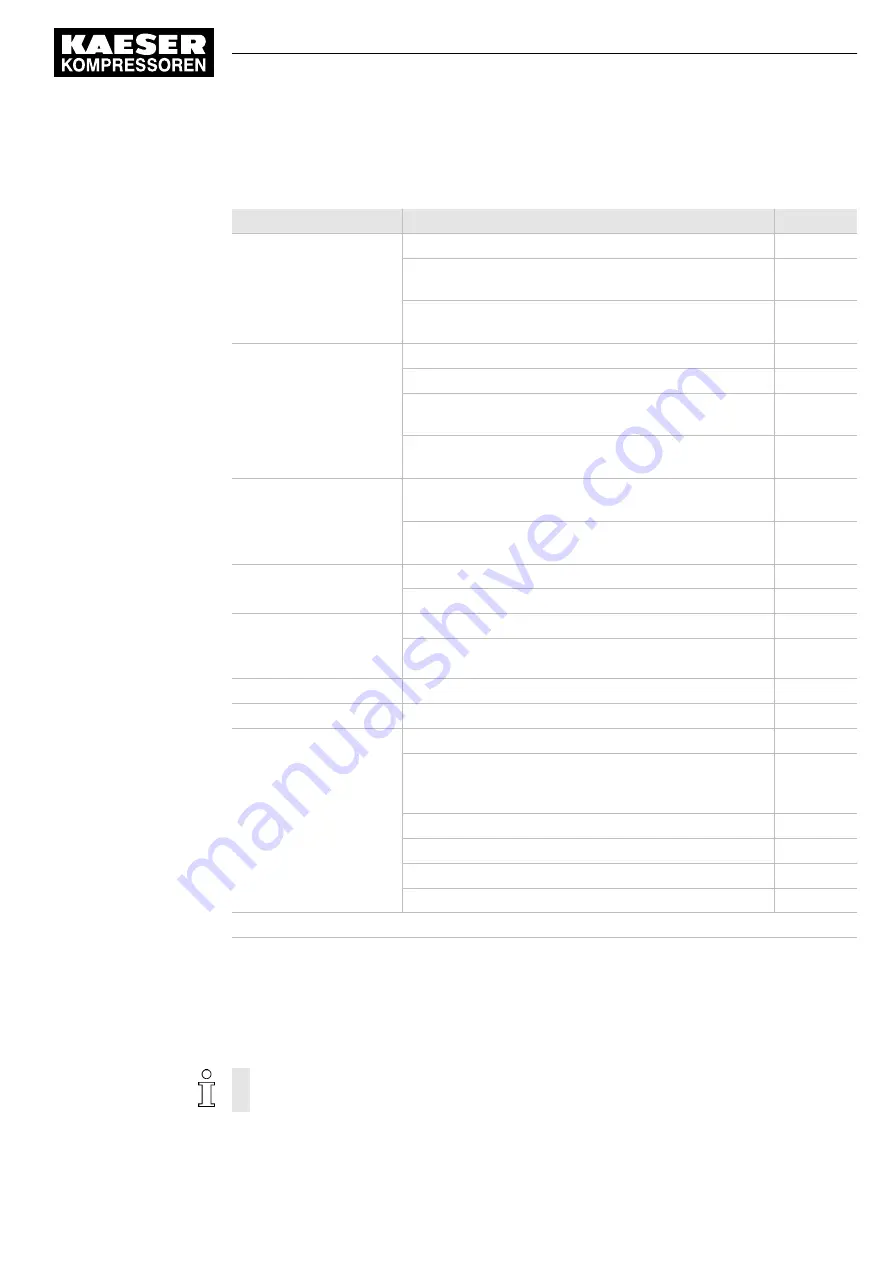

Interval

Maintenance task

See chapter

Weekly

Check the cooling oil level.

Cooler:

Check the filter mat

Control cabinet:

Check the filter mat

up to 1000 h

Clean the cooler.

Check the air filter.

Cooler:

Clean the filter mat.

Control cabinet:

Clean the filter mat.

up to 3000 h

Control cabinet:

Change the filter mat.

Cooler:

Change the filter mat.

Display:

SIGMA CONTROL 2

Maintain the drive belt.

Change the air filter.

Display:

SIGMA CONTROL 2

At least annually

Change the oil filter.

Change the oil separator cartridge.

Change the cooling oil.

up to 12000 h

Replace the drive belt.

Annually

Check the pressure relief valve.

Check the function:

Safety shut-down due to excessive airend discharge tem‐

perature

Check the EMERGENCY STOP device.

Check the cooler for leaks.

Maintain the heat recovery system.

Check that all electrical connections are tight.

–

h = operating hours

Tab. 57 Regular maintenance tasks

10.2.4 Cooling oil Change interval

Duty cycles and ambient conditions are important factors influencing the number and length of the

oil change intervals.

KAESER SERVICE will support you in determining appropriate intervals and provide informa‐

tion on the possibilities of oil analysis.

10 Maintenance

10.2 Following the maintenance plan

901824 12 E

Operating Manual Screw Compressor

ASK

61

Summary of Contents for ASK 28

Page 2: ...Original instructions KKW SASK 2 22 en SBA SCHRAUBEN SC2IO KKW SSC 2 08 20170919 084918...

Page 6: ...Contents iv Operating Manual Screw Compressor ASK 901824 12 E...

Page 8: ...List of Illustrations vi Operating Manual Screw Compressor ASK 901824 12 E...

Page 138: ...13 Annex 13 4 Electrical Diagram 128 Operating Manual Screw Compressor ASK 901824 12 E...