Position Name

Function

5

«Down»

Scrolls down the menu options.

Reduces a parameter value.

6

«Right»

Jumps to the right.

Moves the cursor position to the next right field.

7

«Left»

Jumps to the left.

Moves the cursor position to the next left field.

8

«Up»

Scrolls up the menu options.

Increases a parameter value.

9

«Information»

Operating mode:

Displays the event memory.

10

«Acknowledgement»

Confirms/acknowledges alarms and warning messages.

If permissible: Resets the fault counter (RESET).

11

«LOAD/IDLE»

Toggles between the LOAD and IDLE operating modes.

12

«Remote control»

Switches the remote control on and off.

13

«Time control»

Switches the time control on and off.

Tab. 44 Keys

LEDs

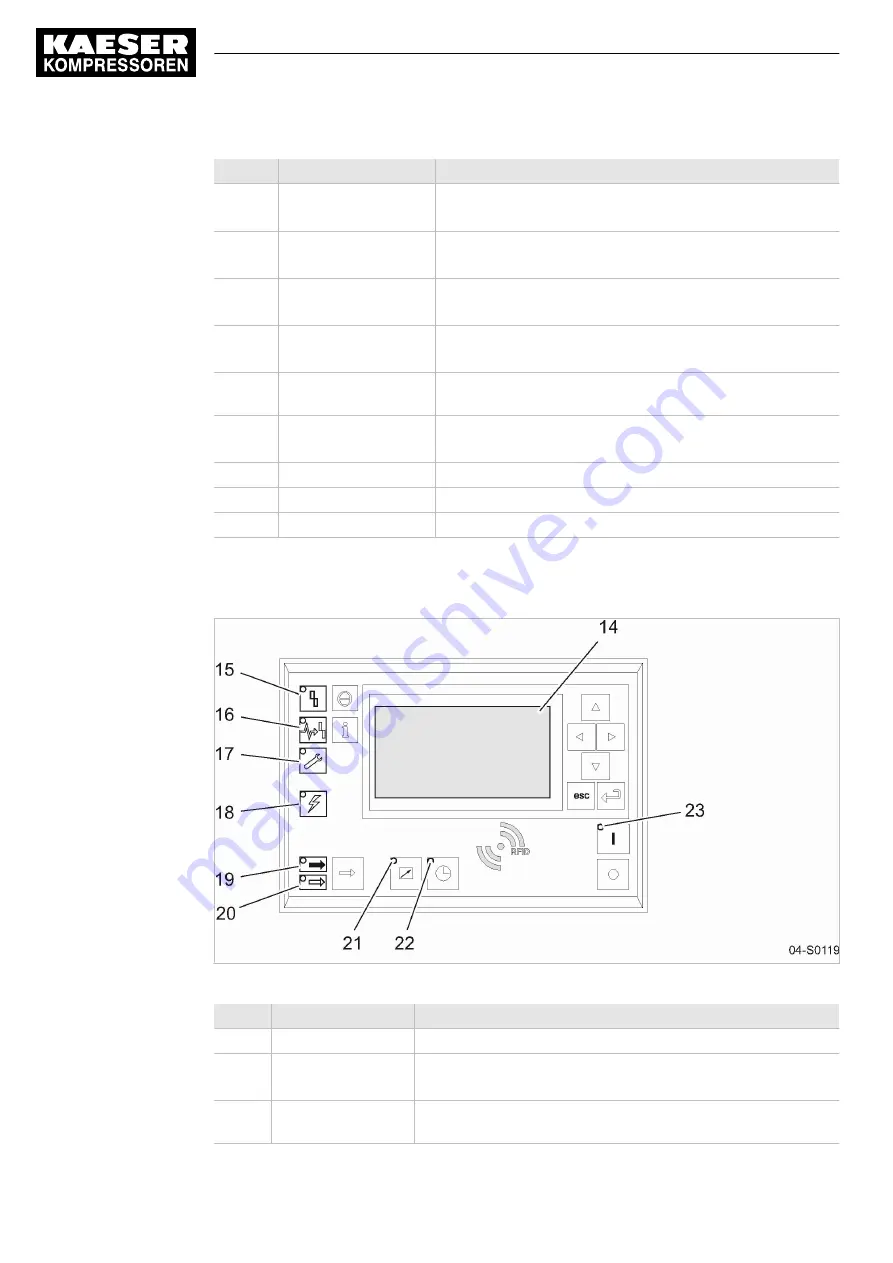

Fig. 6 Indicators – overview

Position Name

Function

14

Display

Graphic display with 8 lines and 30 characters per line.

15

Fault

Flashes red to indicate a machine fault.

Continuous red light after acknowledgement.

16

Communications

error

Continuous red light to indicate a faulty communication connec‐

tion, or an external fault message without machine shut-down.

4

Design and Function

4.3

Operating panel SIGMA CONTROL 2

32

Operating Manual Screw Compressor

ASK

901824 12 E

Summary of Contents for ASK 28

Page 2: ...Original instructions KKW SASK 2 22 en SBA SCHRAUBEN SC2IO KKW SSC 2 08 20170919 084918...

Page 6: ...Contents iv Operating Manual Screw Compressor ASK 901824 12 E...

Page 8: ...List of Illustrations vi Operating Manual Screw Compressor ASK 901824 12 E...

Page 138: ...13 Annex 13 4 Electrical Diagram 128 Operating Manual Screw Compressor ASK 901824 12 E...