1. Check the heat exchanger visually for leaks.

2. Have KAESER SERVICE check the heat exchanger for internal leaks and clean if contamina‐

ted.

10.7 Air Filter Maintenance

Check that all sealing surfaces match each other. The use of an unsuitable air filter element

can permit dirt to ingress the pressure system and cause damage to the machine.

The air filter element cannot be cleaned.

Material Replacement part

Precondition The power supply disconnecting (isolating) device is switched off,

the disconnect device is locked in the off position,

a check has been made that no voltage is present.

The machine has cooled down.

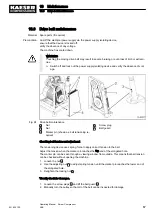

Fig. 23 Air filter maintenance

1

Snap fastener

2

Air filter element

3

Air filter housing

1. Release the spring clips and remove the element.

2. Clean all parts and sealing surfaces.

3. Insert the new element in the housing.

4. Clip the air filter housing onto the inlet valve.

10.8 Motor maintenance

The drive motor and fan motor bearings are permanently greased. Re-greasing is not necessary.

➤ Have the motor bearings checked by an authorised KAESER SERVICE technician during the

course of a visit.

10 Maintenance

10.7 Air Filter Maintenance

66

Operating Manual Screw Compressor

ASK

901824 12 E

Summary of Contents for ASK 28

Page 2: ...Original instructions KKW SASK 2 22 en SBA SCHRAUBEN SC2IO KKW SSC 2 08 20170919 084918...

Page 6: ...Contents iv Operating Manual Screw Compressor ASK 901824 12 E...

Page 8: ...List of Illustrations vi Operating Manual Screw Compressor ASK 901824 12 E...

Page 138: ...13 Annex 13 4 Electrical Diagram 128 Operating Manual Screw Compressor ASK 901824 12 E...