Furthermore, all engines are fitted with various after-treatment facilities. The total of these meas‐

ures contribute to the protection of human health and the environment.

4.7.1 Engine optimisation

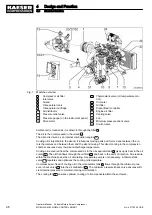

The engine series is equipped with a common rail diesel injection system and exhaust gas return.

The engines are set to a maximum of efficiency and low particle emissions.

Electronic engine management:

The engine system is equipped with an electronic engine management that communicates with the

system controller SIGMA CONTROL SMART.

In addition to monitoring the engine and exhaust gas treatment, the engine control unit (ECU) also

monitors itself. Any faults or malfunctions are stored as fault codes in the alarm memory and for‐

warded to the SIGMA CONTROL SMART controller.

Common rail injection system:

The engine is fitted with a common rail injection system for mixture preparation. It is a high-pres‐

sure accumulator injection system for diesel engines. The common rail injection allows you to opti‐

mise the combustion process so that fewer contaminants are generated whilst consuming less fuel.

The fuel is injected into the combustion chamber from a highly pressurised joint distributor pipe

(common rail). The common rail injection system is controlled by the engine control unit.

Exhaust gas return:

Exhaust gas recirculation is a measure to reduce the emissions of nitrogen oxides. At high com‐

bustion temperatures, damaging nitrogen oxides (NO

x

) increasingly develop in the engine. To re‐

duce these levels, the combustion temperature must be lowered. The cooled and controlled ex‐

haust gas recirculation circulates a portion of the exhaust gas back to the inlet side of the engine

where it is added to the inlet air. This reduces the available oxygen volume and thus the combus‐

tion temperature. Both measures reduce the development of nitrogen oxides.

Exhaust gas recirculation occurs only in the partial load area of the engine because the engine

runs particularly lean in this area. Exhaust gas recirculation is not practical in cold start, warm-up

and full load.

Exhaust gas turbo-charging:

The performance of the combustion engine can be enhanced by means of turbo-charging. A turbo‐

charger compresses the air to allow more oxygen to flow into the combustion chamber. As a result,

more fuel can be combusted and the engine performance increases accordingly. The turbocharger

is driven by exhaust gas which makes turbo-charged engines very efficiently.

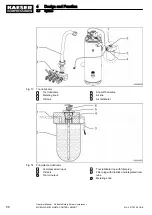

4.7.2 Exhaust gas treatment system

The exhaust gas treatment system primarily contributes to limiting the exhaust gas emissions of

the machine.

4

Design and Function

4.7

Exhaust gas after-treatment

No.: 901783 08 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M82 SIGMA CONTROL SMART

51