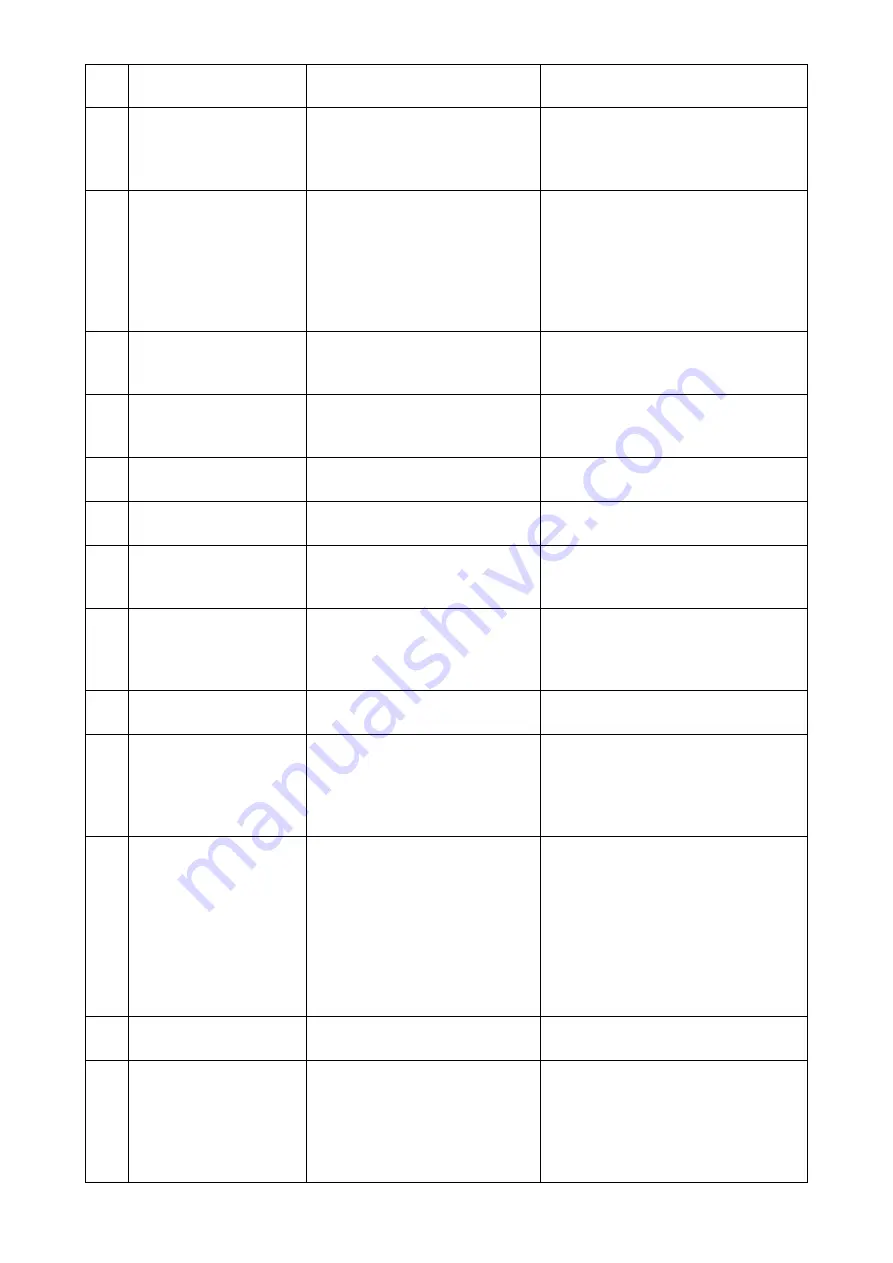

– 54 –

Error

Code

Error description

Fault Cause

Solution

E242 No work IO

1. The work enable input IO signal is

abnormal.

2. Parameter setting error

1. Check the corresponding IO

2. Turn off the “work enable input IO” func

-

tion and set the parameter value to 0

E243 Waiting for input IO

1. Input IO signal in waiting file

2. Corresponding input IO sensor

has bad contact or is damaged or

unable to trigger

3. Parameter or file setting error

1. Automatically disappears when the

corresponding IO is detected

2. Check sensor failure

3. Resetting parameters or processing

files

E244 Execution delay

1. Execute the delay instruction in

the graphics file

2. The delay time is too long

1. It disappears automatically after com-

pleting the delay

2. Reset delay as appropriate

E245

The file name is too long

The file name written in the electron

-

ic tag is longer than 32 bytes (32

English or 16 Chinese characters)

Need to shorten the length of the file name

before writing

E246 Please lift the presser foot

first

Presser foot not raised

Click the "Presser Foot" button to raise the

presser foot

E247 Frame is not pressed down

Unpressed frame

Click the "press frame" button to lower the

frame

E248 Auxiliary frame is not

pressed down

1. Unpressed auxiliary pressure

frame

2. Parameter setting error

1. Click the corresponding IO button of the

auxiliary pressure frame

2. Reset parameters

E249 Frame and auxiliary frame

is not pressed down

1. Unpressed frame and auxiliary

frame

2. Parameter setting error

1. Click the corresponding button to push

down both the pressing frame and the

auxiliary pressing frame.

2. Reset parameters

E250 Punched material has run

out

Out of punching base material

Need to replace the new punch base ma-

terial

E251

Reset failed

The reset fails due to various rea-

sons, such as the origin cannot be

found during reset

Go to "Auxiliary Settings" - "Test Transmis

-

sion" - "Alarm Log" to see which alarms

have occurred during this reset failure.

Refer to the previous alarm faults to re

-

solve these alarms and reset them.

E252

Rotating motor failure

1. Rotary motor alarm due to me

-

chanical overload, etc.

2. The motor wire of the rotating mo-

tor is disconnected, the interface

is loose, and the connection line

between the motor and the driver

is faulty.

3.Rotary shaft driver is broken

4.The rotating motor is broken

1. Check if the machine is stuck

2.Chec k the corresponding wiring

3.Replace the flashing drive

4.Replace the motor

E400 Drive board cannot be con-

nected

Abnormal circuit of main board

Overhaul the motherboard circuit

E401 (0x) Drive board hardware

protection

1. The motor is broken or the motor

wire is damaged and short circuit-

ed

2. The motor is stuck

3. The driver board is damaged

4. The parameters are incorrect

1. Check and replace the motor

2. Check the machinery

3. Replace the Y servo board

4. Reset or redirect parameters