– 55 –

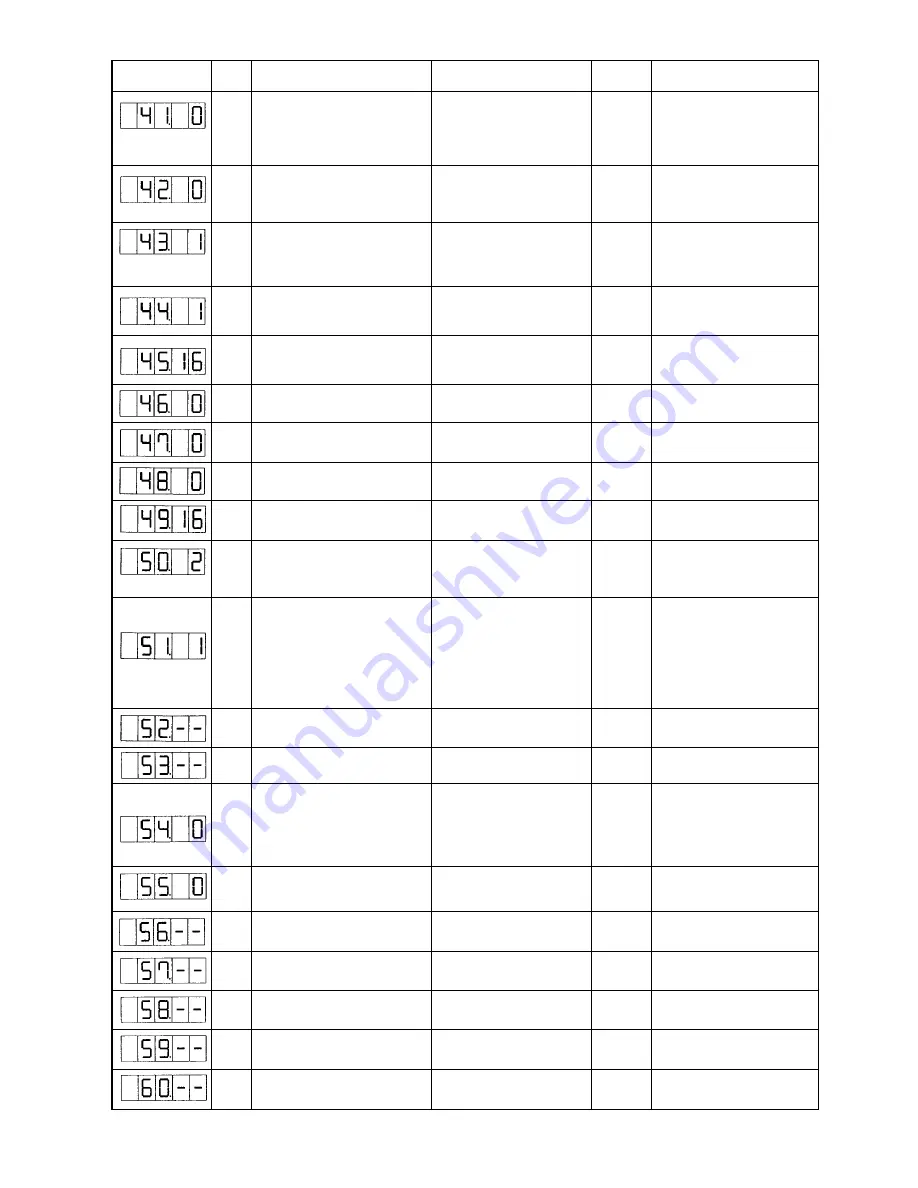

Indication

Level

Functions

Setting range

Remarks

U

State of work clamp foot when

0: Work clamp foot goes up.

0

machine stopped by temporary

1: Work clamp foot goes up

stop command can be selected.

with work clamp foot switch.

2: Lift of work clamp foot is

prohibited.

U

Needle bar stop position is set.

0: Up position (53

°

)

0

Needle bar rotates the reverse

1: Upper dead point (22

°

)

direction after the UP position stop

and stops when upper dead point

stop is set.

S

Selection of sewing machine

0:400rpm

1

This is the sewing machine rpm of the

rpm during thread trimming

1:800rpm

thread spreading by moving knife.

When the sewing machine has

stopped, thread trimmer is function.

S

Selection of whether the thread

0: Feeding disabled.

1

is moved in the direction of easy

1: Feeding enabled.

trimming.

S

Needle hole guide diameter when

16~40

16

When the setting value is increased,

feeding is moved for thread cutting. (1.6mm~4.0mm)

(1.6mm)

the amount of feeding becomes larger.

(Setting possible in the unit of 0.2mm)

U

Thread trimming can be disabled

0: Normal

0

After tentative stoppage, thread

at the end of sewing.

1: Thread trimming disabled

trimming is not disabled.

S

Thread trimming can be disabled.

0: Normal

0

All thread trimming operation is

1: Thread trimming disabled

disabled.

U

The origin reset route can be

0: Linear reset

0

selected with the reset key.

1: Pattern returning

U

Bobbin winding speed can be set

800~2000rpm

1600

(Setting possible in the unit of 100rpm)

U

Operation timing of material

0: Output prohibited

2

For the machines other than

closing is selected.

1: Operation when work clamp foot

LK-1901A, this function is not

(LK1901A only)

comes down.

indicated.

2: Operation at the time of start

U

Wiper operation method can be

0: Without wiper at the time of

selected.

thread trimming on the way

1: With wiper at the time of

1

1

Without return of the last wiper

thread trimming on the way

2

With return of the last wiper

1

(When the setting No. 37:1 of the

2: With wiper at the time of th-

memory switch, wiper operation

read trimming on the way

2

method can not be used.)

3: Magnet wiper

S

Magnet wipe-out time

10~500ms

50

Effective only if the magnet

(Setting possible in the unit of 10ms)

wiper has been selected.

S

Magnet wipe-in time

10~500ms

100

(Setting possible in the unit of 10ms)

S

Wipe-out timing at the time of

0: Sewing machine returned

0

Effective only if upper dead

upper dead point stop

and upper dead point stop

point stop is selected.

after wiper operation in up

position.

1: Wiper operation after upper

dead point stop

U

The stitching at the start of sewing 0: The stitching effective

0

For the machines other than LK-

of the pattern for button sewing

1: Tie stitching ineffective

1903A, thus function is not indi-

can be prohibited. For LK-1903A only

cated.

S

Moving limit range in +X direction

–20~20mm

20

In the state of shipment, no clamp

(right side)

configuration is considered.

S

Moving limit range in –X direction

–20~20mm

–20

In the state of shipment, no clamp

(left side)

configuration is considered.

S

Moving limit range in +Y direction

–20~10mm

10

In the state of shipment, no clamp

(back side)

configuration is considered.

S

Moving limit range in –Y direction

–20~10mm

–20

In the state of shipment, no clamp

(front side)

configuration is considered.

S

Jump feed speed of XY

100~4000pps

2000

(Setting possible in the unit of 10pps)

State when

deivered

Summary of Contents for LK-1900A

Page 20: ... 16 10 Hook adjustment Standard Adjustment 0mm 0mm 7 5mm 0 05 0 1mm For DPX5 For DPX17 ...

Page 90: ... 86 Grease Grease Grease Grease Grease 8 Needle thread clamp mechanism area ...

Page 91: ... 87 Grease Grease A Grease Grease Grease Grease 9 LK 1901A relations ...

Page 92: ... 88 10 LK 1903A relations Grease Grease ...

Page 114: ... 111 12 Circuit diagrams 1 Block diagram A ...

Page 115: ... 112 2 Power supply circuit diagram A ...

Page 116: ... 113 3 Power supply circuit diagram B ...

Page 117: ... 114 4 Power supply circuit diagram C ...

Page 118: ... 115 5 Servo motor circuit diagram ...

Page 119: ... 116 6 Sensor pedal VR circuit diagram ...

Page 120: ... 117 7 MAIN PANEL board circuit diagram ...

Page 121: ... 118 8 Motor solenoid circuit diagram Thread trimmer Lifting the work clamp foot motor ...