Page 15

John Bean VPI System II Operators Manual

NOTE

: Do not use the foot operated shaft lock as a

brake, it is intended to be used only to prevent shaft

rotation while placing corrective weights.

B.

Read the imbalance value on the outer display. Val-

ues are displayed in ounces but can be displayed in

grams if required and are automatically rounded to the

nearest commercial wheel weight.

4.6.1 PLACING THE CORRECTIVE WEIGHT

Raise the wheel guard and turn the wheel until the dis-

plays of the outer plane imbalance position indicator

are illuminated green. A tone will sound indicating top

dead center. Apply the wheel weight at twelve o’clock

position. Use the foot operated shaft lock to prevent

shaft rotation while placing weights.

C.

Correct the inner plane in the same manner.

4.7 VERIFICATION OF THE RESULTS

Lower the wheel guard to spin the wheel again and

check that the readout is

“0.00” “0.00”

If a residual

imbalance is displayed:

A.

Check the rim parameters, if entered value is incor-

rect, correct as needed. Imbalance values will be re-

computed after re-spinning wheel.

B.

Check if the balancing mode selected is the most

appropriate. If not, choose the right mode and respin.

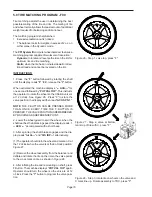

C.

The wheel weight could have been placed at a wrong

position. To check this, position the wheel at the correc-

tion position for the outer plane. If the wheel weight pre-

viously attached is in sector ‘

L

’ or ‘

R

’ ( Figure 25), move

the wheel weight up about 1” (2.54cm).

If the wheel weight is in sector ‘

D

’ cut a piece of the

wheel weight of an approximate value corresponding

to the value shown on the right display, or replace the

wheel weight with a lighter one.

If the wheel weight is in sector ‘

U

’ add a weight of value

indicated by the display or replace the wheel weight

with a heavier one. Repeat the same operation for the

inner plane.

NOTE:

If this situation is repeated, your machine may

be out of calibration and a calibration operation might be

required as instructed on page 21.

D.

If an

ALU

function was selected ensure that the wheel

weights have been placed in accordance to the program

chosen.

E.

Check that the quick nut is tight and that the wheel is

not slipping against the backing collar.

F.

Check that the wheel and adaptors are clean.

Figure 25

4.8 VIBRATION PROBLEMS

If vibration is still present after balancing, check the fol-

lowing possible sources of vibration:

1. Stones caught in the tire tread.

2. Tire slippage on the wheel.

3. Incorrectly mounted wheel.

4. Imbalanced wheel covers.

5. Excessive radial or lateral runout in the tire or

wheel.

6. Damaged wheel bolt holes.

7. Worn universal joints.

8. Imbalanced brake rotors or drums.

9. Worn or damaged balancer accessories

4.9 Weight Call-Back

Pressing this key allows the operator to recall the origi-

nal weight imbalance value and position to check for

proper weight placement in the event the check spin

calls for more weight when in the clip-clip mode. When

the previous balance weights and positions are Called

Back, the LED indicator will light and the letters “tdc”

displayed in center digit window that means “top dead

center check”.

1. Press the Weight Call-Back button to activate the

“weight call back” function.

3. Rotate the wheel assembly by hand until the green

“TDC” LED is illuminated. This is the placement loca-

tion of the original weight amount called out with the

original weight amount shown in the appropriate windows.

Make amount or position correction if needed.

4. Press the [STOP] button to exit the Call Back Func-

tion and the LED indicator will turn off and the “tdc” will

disappear.

Summary of Contents for VPI SYSTEM II

Page 2: ......

Page 27: ...NOTES ...