PART

NUMBER

DESCRIPTION

SERIAL NUMBERS

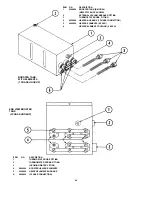

100

3700

Strainer, 'Y', 3/4"

All

1

4000

Switch, rinse/fill (All) (SPDT) momentary slip disconnect

AF24, 451; 2618; 1149

1

0155500

Switch, manual wash (DPDT) (All) Slip disconnect

AF24, 451; 2618; 1149

1

0157500

Switch, master (DPST) (All) Slip disconnect (used on

wash, heat & conveyor on 39's)

AF24, 451; 2618; 1149; 1059

1

0157500

Switch, heat (DPST) (All) Slip disconnect

1149

1

0162500

Switch, start (SPDT) (All) Slip disconnect

1149

1

0165500

Terminal Board, 3 pole, complete

All

1

0166000

Terminal Board, 2 pole, 70 amp, with/mount channel

All

1

0167000

Terminal Board, 9 pole, complete slip terminal

1149

1

0169100

Thermometer, wash or rinse, standard

All

1

0170000

Thermostat, standard (use 0170018 or 0170023)

All

1

0170018

Thermostat, rinse, 180° fixed

1

0170023

Thermostat, wash, 150° fixed

1

0171300

Timer, 220V w/wires and mounting plate, 50 Cycle

(All 50 Cycle)

1

0171500

Timer, 220V w/wires and mounting plate

All

1

0172700

Timer Motor, 220V (for module type timer), 50 Cycle

(All 50 Cycle)

1

0173000

Timer motor, 220V (for module type timer)

All

1

0177500

Timer micro switches, plastic module type (for Eagle Bliss)

All

3

0180000

Track, standard, front or back (use 0180000)

All

1

0180000

Track, comer model, complete (convertible)

All

1

0182000

Vacuum breaker, poppet for 1/2" & 3/4" Febco (obsolete)

BF5490

1

0182500

Vacuum breaker, gasket for 1/2" & 3/4" Febco (obsolete)

BF5490

1

0183500

Vacuum Breaker, 3/4", Watts (use 0184301) (Conbraco)

AF13,034

1

0183501

Vacuum Breaker Repair Kit, 3/4", Watts (use 0184301

)(Conbraco)

AF13,034

1

0184300

Vacuum Breaker, 3/4" Sloan (use 0184301) (Conbraco)

WOO

Vacuum Breaker Kit (float & seal) 3/4'' Sloan

0185000

Valve, 1/4" (for Health Inspector's gauge)

All

1

0186500

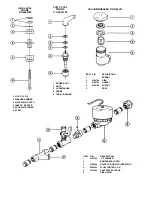

Wash head cap w/race

AF19,035

2

0187000

Wash head cap set screw

AF19,035

2

0187500

Wash head center shaft

AF19,035

2

0188500

Wash head holding bolt

AF19,035

2

0044700

Wash head nut for holding bolt (nylon insert)

AF19,035

2

0193500

Wash head fixed race

AF10,282

2

0194000

Wash head bearings, 1/4", s/s

All

114

0194500

Wash head spray tube ONLY, long length

All

(as required)

0200000

WASH HEAD ASSY., UPPER & LOWER INTERCHANGE

All

2

0200500

Wash head, small manifold w/tubes

All

2

0201000

Wash head, large manifold w/tubes

All

2

0205000

Water level control, Curtis, 220V

AF23,344; 2526; All; All

1

0205500

Water level control, relay ONLY, Curtis

AR23,344; 2526; All; All

1

0206000

Water level control, printed board ONLY, Curtis

AF23,344; 2526; Ail; All

1

0009459

Rack support rod (Vee Shape) Rod only

0008201

Cantilever arm support bracket

0055001

Bottom front panel

0136700

Vertical feed pipe (inside tank) upper to lower rinse arm

0163700

Front door switch (some models) 3 terminal

0163800

Side door switch (some models) 6 terminal

0049801

Spacer Kit tor door wraparound

0138900

Rinse feed pipe support

6047603

Conversion kit straight-thru to corner

049800

Door wraparound

80001

Track rod support assembly

0058200

Heater element, flange tpe 208V, 1500W

0051900

Door plugs black plastic

6047100

Conversion kit corner to straight-thru

54

Summary of Contents for 100 B/PRB

Page 6: ......

Page 26: ......

Page 46: ...45 BOOSTER TANK HEATER ELEMENT P N 0060500 WASH TANK HEATER ELEMENT P N 0058000...