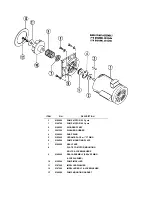

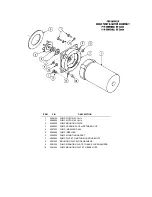

REPLACING SEAL and

CERAMIC on RINSE PUMPS

FUNCTION

The pump is part of the total motor-pump system and utilizes one seal and ceramic to prevent the pump from leaking

around the impeller and shaft. One gasket is used to prevent leakage in between the pump mounting plate and the machine

pump plate.

REPLACEMENT OF SEAL AND/OR CERAMIC

1. Remove power source to machine by turning circuit breaker to its off position on side of control box.

2. Drain machine by removing overflow strainer in wash tank.

3. Support motor - remove the four nuts holding the pump/motor to the machine's pump plate.

4. Carefully pull motor outward, move from side to side as required to remove from machine.

5. Set motor and pump on a sturdy stand close to machine or remove wires and conduit to allow motor/pump to be moved to

a better work station.

6. Remove dust cap over end of motor shaft (opposite impeller end). This can be done by wedging with a screwdriver.

7. Remove impeller - hold shaft by inserting screw driver in slotted end of shaft and unscrew impeller in counterclockwise

direction.

8. The ceramic is embedded in the impeller and normally does not need replacement, but it should be checked for cracks or

a worn out surface. If ceramic does need replacement, proceed as follows.

(a) With a pointed, flat tool, work the ceramic and rubber cup out of groove in impeller.

(b) Clean groove of all residue.

(c) Apply small amount of adhesive in groove.

(d) Press new ceramic gently into groove with rubber cup leading the way. (NOTE:

THE CERAMIC HAS ONE SIDE THAT IS GROOVED. THIS SIDE SHOULD BE FACING DOWN INTO THE

RUBBER CUP. THE SMOOTH SURFACE SHOULD BE FACING UP).

9. The seal is embedded in the pump mounting plate and usually will need replacement when water leaks around motor

shaft area. If replacement is required proceed

as

follows.

(a) Remove four bolts holding pump mounting plate to motor, must be done with Allen wrench.

(b) Slide mounting plate up off of shaft and motor.

(c) Press seal out of housing carefully.

(d) Clean hole where seal was installed.

(e) Apply a small amount of non-hardening sealant to backside of seal. Insert new seal with a seal driver to prevent

ruffling the edges of seal. Never use screwdriver or similar tool to alternately force edge of seal in place.

10. Reassemble pump and motor by reversing the above procedure.

22

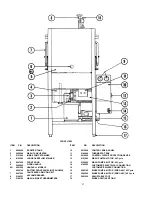

Summary of Contents for 100 B/PRB

Page 6: ......

Page 26: ......

Page 46: ...45 BOOSTER TANK HEATER ELEMENT P N 0060500 WASH TANK HEATER ELEMENT P N 0058000...